|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Member

Join Date: May 2010

Posts: 36

|

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: At my kitchen table in Santa Rosa, Ca

Posts: 2,903

|

how dose it run? drive it!

__________________

If it would have been a snake it would have bit ya! i can't spell my way out of a paper bag! |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,834

|

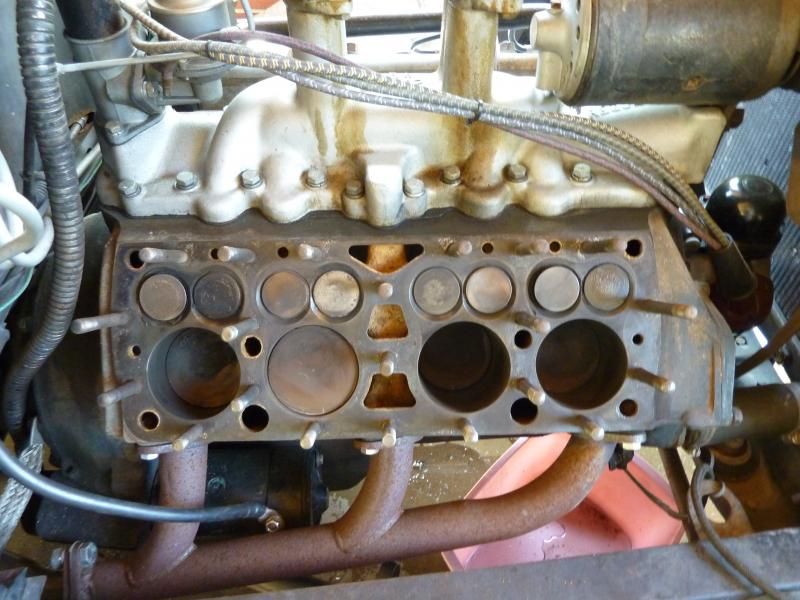

Its actually a 37-38 motor, but apart from that, I'm with Brendan; drive it!

__________________

Unfortunately, two half wits don't make a whole wit! |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Mar 2013

Location: Green Bay Wi

Posts: 400

|

great question, how does it run, does it run smooth idle good, does it use oil and smoke, from the pics doesn't look like anything abnormal to me but maybe we cant see the rust, looks like normal cyl. blueing I put head gskts in mine 3 years ago if I remember it looked like this

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: Near Rising Sun, Maryland

Posts: 10,858

|

If it was running ok and not using oil before you removed the head, I would say clean the carbon from around the valves, the deck, head surface, etc., and put it back together with a new head gasket. You might be wringing your hands and over worrying needlessly.

If it turns out that a rebore is really necessay, the '37-E'38 21 stud blocks can be bored more than the earlier 21 stud blocks. Walt Dupont usually takes them up to a 3-3/16" bore (0.120" over).

__________________

John "Never give up on what you really want to do. The person with big dreams is more powerful than one with all the facts". Albert Einstein Last edited by JM 35 Sedan; 05-06-2014 at 07:53 PM. |

|

|

|

|

|

#6 |

|

Member

Join Date: May 2010

Posts: 36

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,834

|

JM has answered that question; you 'should' be able to go out to .125" oversize with that particular block

__________________

Unfortunately, two half wits don't make a whole wit! |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,754

|

If you hadn't cross threaded the plug hole, would you have been happy to continue running it, even though it smoked a little?

Can anyone back up JM's statement that these motors can be bored +.125? How about the distance between the lower stud and the cylinder bore and gasket sealing ring? It looks pretty close to me. Furthermore, is a gasket available for a 21 stud with a 3-3/16" bore? No disrespect, JM. I have one of these motors myself and would like to see that statement confirmed. I know the 59 series engines were produced in a 221 cu in version as a service replacement and those can be bored to 3-3/16" as the castings are the same. Could there be confusion between 221 cu in 59 and 21stud? Mart. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Jun 2013

Location: Kolding, Denmark

Posts: 129

|

You don't need to remove head to repair plug thread: I used an insert and the tool to put in new plug thread in my aluhead.

Regards, Christian |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Jul 2010

Posts: 2,593

|

Mart, the castings of the 221ci and 239ci 59 engines aren't the same, the 221city has thinner cylinder walls. And the smaller bore. They won't bore as Big as the 239ci. I think I've said before, I think Glen had a 21 stud bored to 3 3/16". Yes you get close to the bottom stud, but it does go. Theirs also a 255ci 21 stud build in the Tex Smith flathead book. And Don Ferrara had a 1937 engine bored to 3 3/16 + 0.60. There more but they are from the top of my head. As far as I know big bore gaskets went/arnt available for the 21 stud. Stock gaskets appear to be ok for use. If you look at the pics above, that's 0.080" over at 0.125" over the bore edge would still be under the fire ring, the piston edge on stock pistons doesn't normally reach the deck surface, so no problems with them hitting.

Martin. |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,754

|

Cheers, Martin, thanks for the clarification.

Mart. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Gardiner Me.

Posts: 4,200

|

The 36 and older engine have thin walls and I don't recommend over .060 the 37 up will go .125 to 3-3/16. I've done many, Back in the early 50's they were the hot no. on the dirt tracks. Walt

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: Near Rising Sun, Maryland

Posts: 10,858

|

Walt, based on your experience, can a '36 LB block be safely bored over 0.060" or is it in the same category as a babbitted '36 and earlier 21 stud blocks? Just wondering.

Also, many thanks for being such a good teacher for us on these Flatheads!! Our visit to your shop during the Maine Tour was definitely one of the high points for me.

__________________

John "Never give up on what you really want to do. The person with big dreams is more powerful than one with all the facts". Albert Einstein |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Feb 2014

Location: Nor-Cal

Posts: 140

|

Put 70wt in it and drive

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Jul 2010

Posts: 2,593

|

Zgears, To answer your questions. Yes it almost certainly will bore to 3 3/16", this is what you refered to as 24 stud size. 24 stud came in 3 1/16"(same as 21 stud) and 3 3/16". Yes it can be sleaved back down to std 3 1/16".

I can clearly see the rust marking on the bore. Mut have been sat awhile with water in the bores.Yes is should really be bored out, But if it were my toy, I'd slip the head back on after de-coke, drive it till winter. Then sort it. Or the next winter. I'd get round to it at some point. But wouldn't worry my self over it, depends really on your definition of "smokes some" the valves and pistons dont look realy oily. Martin. |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,436

|

In all eventuallity, the old motors will have to be sleeved at some point. I wouldn't sleeve one until I had to though. It still runs around $100 a bore so it is still less expensive to find a good block but one day a good block may be the only one you have that isn't cracked or repaired in some fashion.

The Tex Smith book build bored the block to fit 3 3/16" sleeves. They also used JB Weld on the sleeves to try and maintain the deck dimension since I'm sure they bored though the original walls to get those sleaves in there. That was an interesting build but I'm sure they spent a lot of money and time to make a bigger motor out of a smaller one. That build was for a Great American Race 35 coupe entry sometime back. |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,754

|

I'd put the old head gasket back on too, if it looked like it had half a chance of working!

Mart. |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Posts: 1,835

|

Myself if the block was good and crack free I would be looking into sleeving down or back to 221. Being a machinist I never got the concept of boring a size extreme to the original,most Barners it seems are in favor of doing this,you would never do this to say brake drums oversize beyond limits. I would rather have the dependabilty of a cooler running engine, I have a chart that shows a flathead engine from standard to .030 should be in normal heat range,0.060 should run 185F .0.090 over 195F and 0.125 over can get you 210 F.

__________________

"Never complain,never explain"... Henry Ford II |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Sep 2013

Location: East Fork Satsop

Posts: 611

|

I am new to the Flatheads so I am going to ask a question that may be common knowledge. I don't know if these castings had a issue with core shift but wouldn't it be wise to have the block sonic tested prior to boring to make sure the block had enough material to be board that far safely?

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Jul 2010

Posts: 2,593

|

Yes they can have core shift, lots do sonic test when going real Big. Most flatheads have very thick walls compared to other stuff.

The chart, overbore to heat numbers. How does this work when different flatheads have different thickness cylinder walls? For instance, pump in head is maxed out at about 0.060" over, and 99A can sometimes go up to 3 7/16" ? Martin. |

|

|

|

|

|

#21 | |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,527

|

Quote:

|

|

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,527

|

Regarding that chart. I'm sure no one believes that cast iron would be considered a good insulator, then how can it be possible that a .060 difference in wall thickness could produce 40 deg higher temperature? I don't think so.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2010

Posts: 1,835

|

I was just trying to show a comparison and this was the first thing I thought of. I worked for forty two years with knowing what was a standard size on various parts so I guess it is just a part of me to always try to be at that standard and not over or under whether an engine bore or brake cylinder or a rifle bore or anything designed and machined a certain size,way overboring is just not for me and only my opinion I guess.

__________________

"Never complain,never explain"... Henry Ford II Last edited by 37 Coupe; 05-07-2014 at 01:12 PM. |

|

|

|

|

|

#24 | |

|

Senior Member

Join Date: May 2010

Location: Gardiner Me.

Posts: 4,200

|

Quote:

|

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 10:17 AM.

Linear Mode

Linear Mode