|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,860

|

I don't have anything against ARP bolts, because they're definitely a quality item. The company has a very good advertising agency working for them , as every time you see an engine build on TV or the web sites , they all use a ARP bolts , and if your not using ten, your making an inferior product, and for between 30 and 60 dollars we can sell you some screws that will hols you oil pan on better than the original ford ones. Now allot of new people seem to believe you have to use these parts when rebuilding you engine, and that in clues the 120 hp flatheads. I have NEVER used an ARP bolt on any engine i ever built and that includes several Hems. When I built engines, most guys thought I charged too much. I'm glad I don't do that any more and with the cost of building them in the future, most people won't beagle to afford them.

Gramps |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Dec 2013

Location: Minnesota, Florida Keys

Posts: 10,319

|

I have to agree with Ron on this. I always thought ARP fasteners, while quality parts, were seriously over priced. Since I don't build ultra high performance engines, original Ford hardware in good shape has always been fine.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,181

|

C'mon, guys. That's like saying Porterhouse steaks suck because they cost too much. Let's not go down this road. If you buy them right, they aren't that much more.

Use what you want, but don't speak opinion as fact. |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Oct 2015

Location: Socal

Posts: 795

|

My comment is not really flathead oriented but there are definitely applications where the OE fastener was a POS design or under-sized. 289 Ford connecting rod bolts come to mind but there are others. I won’t use anything but ARP in that application.

ARP has definitely evolved in quality and in price. “Way back when” engine builders wouldn’t touch ARP..... I used to use SPS back when I did race stuff. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2012

Location: Ontario, Canada

Posts: 123

|

Don't need ARP to hold on tin parts but love them for rods; mains and head bolts.

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Dec 2013

Location: Minnesota, Florida Keys

Posts: 10,319

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Oct 2019

Location: Carthage , Tennessee

Posts: 199

|

Lol,,,,,some applications they are worth it .

Mains,,,rods. Heads,,,,,studs and bolts sometimes need an upgrade . But,,,,oil pan bolts,,,,,nope . And,,,,,the factory rods in flatheads have the bolts forged into them,,,well cast I think is the correct term . Factory rods seem to:work very well in a Flathead ,,,,,don’t they ? Now,,,,these rods were designed and used in a 100 hp engine,,,,,not a 400 hp high performance engine,,,,right . So,,,,,go with what you need to make it live . Also,,,,,,the factory hardware from back then is still top notch quality,,,,,very tight tolerance in the head bolt holes,,,,and very good steel in the crankshaft. Remember,,,they used to weld these cranks and make strokers from them way back then . Like I said,,,,,,if you feel you need better grade parts,,,go for it . My little 8BA will probably make 145 hp or so after my upgrades,,,,,so I’m not terribly worried about the aftermarket stuff all that bad . Tommy |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,834

|

So, I guess the bolts in this thread; https://www.fordbarn.com/forum/showthread.php?t=295953

weren't ARP? lol

__________________

Unfortunately, two half wits don't make a whole wit! |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

I miss the options of fordbolts and roy. I have used arp a couple times. Replaced bolts on a ridiculousness idea for a yblock flywheel hardware idea, of saving a dollar on bolts and put grade 8 hardware bolts in. Changed those out when I came to my senses. There are substitutes and don't have an issue with reusing ford bolts.

I get what OlRon is saying. It's not the only option. It's a good option. I guess I have a issue with the look of the fasteners and the quality when it comes to the visual aspect when it's shown (which is available) I don't want allenhead bolts on a stock car when it's seen. No issue with internal bolts. Nobody is going to see them. Last edited by Tinker; 03-19-2021 at 12:54 AM. |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Dec 2019

Location: Gardnerville, Nevada

Posts: 185

|

I have found that the standard 7/16 stud that you would purchase from your average parts store for the heads are not concentric, from end to end. If you put them in a lathe using a 7/16 Collet , holding by the coarse thread and the by the fine thread you would not believe the amount of runout that they have ! The ARP Studs are more expensive no doubt about it. When you have a total of 24 studs with that much runout I think it creates an interfearence problem with the cylinder head. This is just my opinion. I prefer to use ARP studs that are very concentric. Yes they are more exspensive. Stan

|

|

|

|

|

|

#11 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,181

|

Quote:

https://www.allensfasteners.com/ You need to do a little leg work and know what length you need, but well worth the effort. Speedway is overpriced on ARP stuff. Last edited by Tim Ayers; 03-19-2021 at 07:50 AM. |

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Oct 2019

Location: Carthage , Tennessee

Posts: 199

|

Good idea Tim,,,,,do some shopping and save a lot of money .

Still top quality,,,,but a lot less expensive . Even though my 49 Merc came with head bolts,,,I am planning on using studs when it goes back together . I want to make sure the seal is there for water,,,,,and then the clamping force,,,just to add an extra peace of mind . Tommy |

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,181

|

Quote:

That thread is what got me thinking about this. Did Ford make or have quality OE hardware made? Without question. For a few dollars, why wouldn't you use known quality hardware in critical spots? Without the proper knowledge or understanding to know what to look for, you could be using a bolt that is past it's life expectancy and is ready to let loose. We see what damage that can cause. I've come to the realization that time is just as expensive as money the hard way. Redoing stuff or having stuff fail because you went cheap is no cost savings at all. It actually cost you more in the end. Last edited by Tim Ayers; 03-19-2021 at 08:29 PM. |

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,860

|

As fa as head bolts are concerned, a grade#5 hardware store bolt would be more than adequate to hold the head on in ever a highly modified engine. When torquing a bolt to yield to reach it's greatest strength/ when installing a head on the flathead with 24 7/16 bolts to 45 ft/lbs three 3 heat cycles, you have not exceed the yield strength of the bolt. I worked in the machine industry (Bulards) and bolting thes together, considering the application , the number and size of the bolts had to be determined. I'm sure sonething like this is part of every automotive manufacture and the stock bolts used in the flathead were probably designed to exceed the maximums load load on them by at leas 100&. I think the fasteners are made from Ford E Steel.

Now I don't suggest you buy some Chinese grade#5 bolts, but befor you say the stock bot is not strong enough, why?????? Now if i was running 20 lbs of boost, I might consider ARP bolts. |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Aug 2018

Location: Ottawa, ON

Posts: 855

|

I agree with Ron. After waiting for an eternity in trying to source some Gr 8 flanged head bolts from Hillman, I broke down and purchased some ARP flange head bolts from Allen Fasteners. I believe there were about US$175.00 which is a reasonable price considering the price I’ve seen with some vendors for stud “kits”. I ultimately just went with Gr 8 Hex Hd bolts from Caterpillar. I believe these bolts were about CAN$100.00, and match the orig Ford bolts very closely with the only difference being a slightly less thick head.

Last edited by Ziggster; 03-19-2021 at 02:59 PM. |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Location: Shenandoah Valley Virginia

Posts: 220

|

I look at ARP fasteners as an insurance policy to hold my very high revving SBC engine together (302 Trans Am race engine). Quality control is more important to me. They are cheap compared to the overall cost of the rest of the parts on that engine. Sort of like comparing cast parts to forged parts for rotating assemblies.

I would never consider them for my 286 inch Ford flathead engine.....loads/stresses are quite low. Last edited by hotrodart; 03-19-2021 at 03:11 PM. |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: Mar 2014

Location: Jacksonville FL

Posts: 3,963

|

Where ARP has it over the majority of "fastener" suppliers like me IS......ARP is catering to the automotive/automotive racing industry and I would bet, the latter more than the earlier (ie you pay a "headache" fee)......AS the earlier yield way more in profit THUS increasing the profit (or makes the latter more cost effective) of their main-line business. Back to my original comment......Fastener suppliers like me cater to the "Heavy Industrial" and "Commercial" market, where "most" diameters and or thread pitches match exactly.....THE "FORM" of them does NOT.....AS mentioned above and "Flange Headed" bolts!!! I'm my 23 years of supplying bolts, I have yet to find a plumber, electrician, boiler maker or steel hanger "needing" a flange head bolt!!!! NOR do they care about the "straightness" down to thousands of an inch!!! SO commercial supplier like me are NO competition for ARP cause IF we did ARP wouldn't be near as expensive. Niche' market comes to mind!!!!!

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,409

|

ARP is good stuff but for several applications not necessary if you have a lathe.

I have built quite a few all out vintage circle track flathead engines and have never bought a specialty fastener other than the rods I use come with them. I make main and head studs by single pointing them in a lathe so I know they are concentric and the thread will have a polished finish. The thread also has a slightly modified configuration.I then have them heat treated to my specs. The final cost is comparative to what ARP sells them for. |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Dec 2010

Location: East Coast in CT

Posts: 1,529

|

Seriously I'm amazed this is really a topic for this forum. Your not interested in buying the best quality available so be it. As Tim wrote you can find the product at extremely fair prices. And as Pete wrote making hardware yourself you can have quality that way but it takes time which adds up to money.

Wasn't there recently a post for someone who experienced a center main bearing cap failure? Was it caused by stock appearing bolts? Makes you wonder a bit more cash for quality or will stock more than due. Sometimes maybe not! Ronnieroadster

__________________

I use the F word a lot no not that word these words Flathead , Focus and Finish. "Life Member of the Bonneville 200 MPH Club using a Ford Flathead block" Owner , Builder, Driver of the First Ford Flathead bodied roadster to run 200 MPH Record July 13, 2018 LTA timing association 200.921 in one and a half miles burning gasoline. First ever gas burning Ford flathead powered roadster to run 200 MPH at Bonneville Salt Flats setting the record August 7th 2021 at 205.744 MPH Last edited by Ronnieroadster; 03-19-2021 at 05:31 PM. |

|

|

|

|

|

#20 |

|

Member Emeritus

Join Date: May 2010

Location: Fitzgerald, Georgia

Posts: 2,204

|

There are NO fasteners in a stock or modified Flathead engine which have their capabilities exceeded unless there is a defect or other compromising influence in the fastener at the time of installation. PERIOD.

|

|

|

|

|

|

#21 |

|

Senior Member

Join Date: Oct 2019

Location: Carthage , Tennessee

Posts: 199

|

JWL,,,,,Amen .

Tommy |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,068

|

There are few 100% applicable answers from the above posts - for all the situations and conditions related to stock, high performance and racing.

The same fasteners that work for 100 HP on the bottom end are probably not the same ones you want to use for 400+ HP. How many of us have retorqued the mains - through multiple heat cycles? (I never have). How many times have I torqued stock head studs and then had to come back multiple times before they ever held the previous torque value . . . ask yourself . . . Hmmmmm . . . why is that? Did the stud/bolt continue to stretch maybe? Did my main studs stretch as well - and truthfully, I never knew it? Maybe . . . I use mostly ARP studs for a variety of reasons. #1: When I torque them to a specific value, they hold their torque to a very similar amount to what I started with. #2: Head Studs: Given the "concentric" post up above, I used to have to align/bend the studs with a brass hammer to get them to be straight and fit my heads. And I had to hope and pray that I could get the damn heads back off the thing without having to use all sorts of "pry bars" underneath them. I've pried all sorts of aluminum heads off of flatheads - in some cases having to surface the heads as a result of the abuse they were subject too on disassembly. When I put ARP head studs in - I have the luxury of using the Allen head socket to remove the studs - before I pull the heads. This makes disassembly a WHOLE lot easier. Once you've used this approach, you'll probably never go back to screw drivers and pry bars. So, does one need ARP fasteners for stock or mild performance engines - heck no. But, when you put a bunch of these engines together and take those same engines apart, you'll really appreciate that you spent a few extra hundreds of dollars on studs and hardware. What did you spend on the rest of the engine . . . was this the place to save money? (In my mind, "No" - but I build stuff on the higher end of the scale). Lastly, I think we all know that there are many different types of builds and associated budgets. What works for a low-price build is not the same as a high-end build with thousands of dollars in it. If you're building a $10,000+ flathead, having a few extra hundred dollars of ARP fasteners in it - not really a big deal. When you're rebuilding a stock engine on a very small budget - then by all means, use whatever you can that Henry supplied - he made really good fasteners and most are better than almost anything you can buy off the normal hardware store shelf. I'd probably use Henry's studs over any "stock replacement" aftermarket product. Enough out of me . . . time for what Pete and I call a "Martoonie"! LOL |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2010

Location: Auburn, MA

Posts: 2,106

|

I always thought retorquing the heads was because of the gasket squish and taking a set. Never heard of a bolt needing to be checked for stretching.

__________________

“The technique of infamy is to start two lies at once and get people arguing heatedly over which is true.” ~ Ezra Pound |

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 353

|

IMHO, If you are getting bolt strech on flathead head bolt @ 45 - 55 ft # torque, you have a bad bolt. They should handle many, many #'s of more torque before they could strech. I would think that the threads in the block would let go before the head bolts would even think about streching. Just sayn.

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,068

|

Take some time to look up what clamping force and bolt/stud stretch is all about. Look into how companies like ARP (and pretty much all the high-end rod builders) recommend that instead of using a torque wrench to determine the proper tightening for rod bolts - you should really use a "rod bolt stretch gauge". These gauges are specifically designed to measure the amount of rod-bolt stretch - as a means to determine the correct amount to tighten the bolt.

Also, the materials used in ARP's 7/16 rod bolts are a heck of a lot stronger than the materials used in typical head studs - yet stretch is used to determine correct fastener load. Fasteners stretch - some a lot more than others . . . When I switched over from stock studs to ARP studs, you can feel the difference on the torque wrench. Hard to explain unless you've done it - but I assure you it is true. The ARP studs tighten in a very firm manner - unlike the stock studs and nuts (even with the correct hardened washers on aluminum heads). Here is a little article that you'll find interesting: https://hotrodenginetech.com/how-to-...ted%20practice. |

|

|

|

|

|

#26 | |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,409

|

Sponsored Links (Register now to hide all advertisements)

Quote:

|

|

|

|

|

|

|

#27 |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

Well using anti seize will change the bolt torque. It's been discussed here. I like anti seize. For the average joe a set of studs used or other will be fine. Watching these kids on media putting turbos and whatever on them. Ya whatever. You need to do more. Not that bolts will save the motor.

Last edited by Tinker; 03-20-2021 at 10:46 PM. |

|

|

|

|

|

#28 | |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,114

|

Quote:

|

|

|

|

|

|

|

#29 |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

I didn't miss anything. Even ARP has conditions for anti seize and torque settings. Guess lube is lube. I'm not making a big deal about it. A bolt sitting on the bench has very little torque and don't think it'll grow.

https://arp-bolts.com/p/arpultratorque.php The old thought was about 5lbs on studs with anti seize. Oh course re torque the heads. Well what is old is no longer new. 99% of us can't say their torque wrench is within 5lbs accuracy anyways. . Last edited by Tinker; 03-21-2021 at 02:12 AM. |

|

|

|

|

|

#30 |

|

Senior Member

Join Date: May 2010

Location: Auburn, MA

Posts: 2,106

|

The torque wrench was not even invented until 1924 and I'm sure a lot of garages did not have them in the 30s and maybe 40s.

A threaded bolt is the equivalent of an inclined ramp. Thread pitch determines the ramp angle. Finer threads generate the torque with less effort but over a longer distance. Someone mentioned measuring bolt stretch and that is a definitive measurement. It does not matter about thread or lubricant, you're measuring the distortion of the bolt caused by the clamping force. Another definitive measurement is angular movement. It might not be quite as accurate as stretch but if you turn a wrench 90 degrees on all the bolts then you are uniformly applying clamping force. Some may turn harder or easier but you are pushing on all the studs/bolts with equal force. That is given they are all starting at the same point and some manufacturers say to establish 20 ft lbs and then so many degrees to reach final torque. Now when you are doing strictly force the use of lubricants makes a big difference. A well oiled main bolt to 95 ft lbs will exert more force than a dry bolt at the same setting. It only makes sense. Also a running torque is different than a static one. Some recommended loosening a head bolt before retorquing. You have to overcome the initial friction to get it moving. A moving bolt has less friction. Take it for what it is worth but this is from Snap On's website about their history. Precision Torque In the late 1930s, Snap-on responded to the need of taking the guesswork out of applying torque. Snap-on reached an agreement with Precision Instruments, Inc. to manufacture “Torqometers.” The torqometer is a wrench and gauge combination that ensures accurate and uniform nut tightening, providing proper clamp loads and durability. Snap-on was one of the first companies to offer a complete range of torqometers, which were essential in automotive, aerospace and industry, and enjoyed a patented position in the market for many years.

__________________

“The technique of infamy is to start two lies at once and get people arguing heatedly over which is true.” ~ Ezra Pound |

|

|

|

|

|

#31 | |

|

Senior Member

Join Date: Sep 2014

Location: Wiscasset, Maine

Posts: 1,981

|

Quote:

BTW, when a stud or bolt shears straight across the diameter, it failed in tension. If it fails at 45° across, it is a torsion failure. This is a good site for various tightening methods. https://www.boltscience.com/pages/tighten.htm |

|

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,181

|

I really find this discussion very interesting. If you search you will find numerous post with guys complaining about the cost of building an engine and how things cost way too much today.

It could just be me and I'll admit that, but do you really want to put faith in bolts and fasteners, that in some cases, are close to 80-60 years old? You truly don't know what has happened to these bolts prior to you reusing them. I agree with Ronnie Roadster, Pete & Bored & Stroked, when you've got $6K-$10K in a hi-po street engine, what's another $300? In the grand scheme of things, it's nothing. I know everyone is in a different place and some folks have a very tight budget for this hobby, but for $300 (not $500 like Speedway's price), why would you not use the best that you can get? Is it worth fighting studs to get heads on? Is it worth the hassle of trying to get them out without the hex head? Is worth fighting leaks and other issues that inferior studs can cause? In the end, you do need to ask yourself, how much is your time worth? I'm seriously asking and maybe I'm wrong in my view point. Last edited by Tim Ayers; 03-21-2021 at 09:35 AM. |

|

|

|

|

|

#33 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,860

|

I never thought this thread would be as educational as it has been. I have learned allot. In all the years I've been building engines, I've never thought of using an aftermarket fastener., back in the day ARP didn't exist so the SBC, Big Olds and those nasty Hemis got putt together with what ever the factory provided. Never lost an engine. Two e of my flatheads lost the 1,5 rod bearing, I fixed one and Walt fixed the other. He said it was from oil failure. In future builds I drilled out the supply hole in the front main bearing to the next size. The small 258 Hydro engine was the scary one, spent most of it's life between 5/6 grand and pushed the boat (Baby Ruth) over 60 mph on many ocasions. It was replaced by a 284 that couldn't go quit as ast. It was dynoed at 175 HP @ 4800. I think the major reason for this was the wrong Prop I still can't justify the cost of some of thes bolts. I use stock head bolts, Main bolts. I use SBC nuts on the stock rods. Which brings up a point. IN all my flathead race motor I use floating bearings on 21A, 91A, 29A rods and when you look at them, you wonder how they can stand the power they can produce. At present, I've designed a new intake port for the flathead. Not as complicated as it sounds. The Key to this is the chevy Vortec cylinder head which increased the power of the SBC 40HP with SMALER VALVES. Later the LS engines were born. The only thing that makes horsepower is the air we breathe. course, Nitro helps.

Gramps |

|

|

|

|

|

#34 |

|

Senior Member

Join Date: Oct 2015

Location: Socal

Posts: 795

|

SPS Tecnologies existed. They've been manufacturing "hi zoot" fasteners since 1903 as Standard Pressed Steel Company. They are (& were) an OE automotive supplier.

ARP just got started in the fastener business yesterday, in comparison. They are purely an aftermarket concern in the automotive business. |

|

|

|

|

|

#35 | |

|

Senior Member

Join Date: Dec 2013

Location: Minnesota, Florida Keys

Posts: 10,319

|

Quote:

Any of you who have been around here long enough might remember my thread on positioning the heads using lengths of aluminum tube, the one on angle milling a head to match an incorrectly decked block, and my constant concern about properly fitting the heads to obtain optimum quench. I believe that attention to detail in such matters is a lot more important than a set of $300 fasteners. It should be known that over the years I have built up a sizeable supply of 8BA head bolts all carefully inspected and prepared, so I have a reasonable alternative. I go into this as I believe that this is primarily a forum for hobbyists, many of whom are looking for help and information. I'd hate to have them come away from here with the impression that installing their heads is mainly a matter of purchasing a set of expensive fasteners when there are a lot of other factors involved. I know there are many reputable professional builders on this forum as well who have their own reasons for what they use, but they already know what they need and don't need any additional assistance. What's sauce for the goose might not be suited to the gander. |

|

|

|

|

|

|

#36 |

|

Senior Member

Join Date: Oct 2019

Location: Carthage , Tennessee

Posts: 199

|

Like has been said,,,it all depends on the application .

High horsepower or race engines deserve and require the best,,,,no way around that . Where stock or warmed over engines can probably get away with standard parts . I don’t blame anyone either way . I see on Reds Headers he has some very well priced stud sets that I think are listed as ARP . Migh5 not be the ultra top racing stuff ,,,I’m not sure . But,,,I might give them a try . I wish there was a register where you could see how many of these old engines are still in service,,,,,and how many cores are available for future service builds . Im Certain there is a large number still around . Tommy |

|

|

|

|

|

#37 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,068

|

The good part of this thread is that we all discussed a LOT in reference to fasteners, technology, torque/clamping force, costs, etc.. And given the application, HP levels, budgets, perspectives/beliefs - there are options to consider.

In the end, we all have to live within our (or our customer's) budgets. We decide where to spend money, where not too - in the never ending attempt to get the best we can afford - spending money how we best see fit. Thanks to all the contributors to this thread . . . has been fun.

|

|

|

|

|

|

#38 |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,114

|

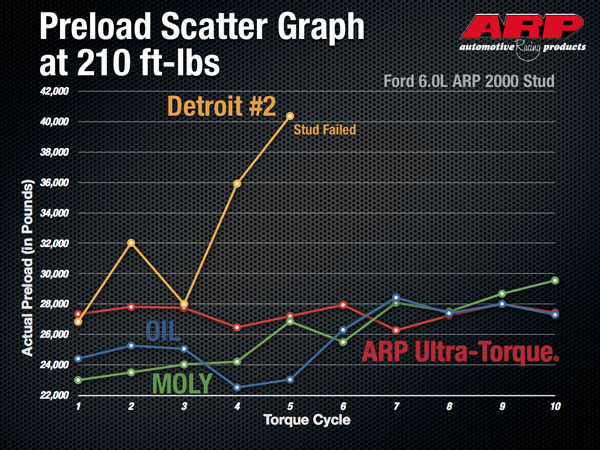

.

glennpm ......You CORRECTLY noted my statement above (QUOTED directly below) as utter BS when taken at face value....and that is MY FAULT! My original BS quote: "In fact, measuring 'bolt stretch' really has nothing to do with torque." OF COURSE torque must be applied to fasteners to generate the clamping force that culminates in the event which we call "bolt stretch". And most of us realize that measuring bolt stretch of (for instance) an "ARP" fastener to see if the fastener has met a pre-determined (by ARP Engineering) 'length', is a generally-accepted, precision method of assuring a pre-determined clamping force. ARP's own site mentions "repeatability" as an important factor in using this method. Through their own manufacturing standards involving fasteners, as well as through the EXCLUSIVE use of ARP's own proprietary thread lubricant ("ARP Ultra Torque"), generally assures 95-100% of recommended preload on the first cycle. THEN.....you measure the stretch! I had taken issue with a previous poster arbitrarily, straight out of left field, throwing "anti seize" into this picture. You might as well say that a bent nail is every bit as good as a proper cotter pin. His subsequent justification was..."Guess lube is lube." As we can see below in one of ARP's graphs, there is no "GUESSING" to it.....Lube obviously AIN'T all the same! Using ARP's prescribed product(s) essentially guarantees that a repeatable degree of torque applied....will result in the predetermined length measurements one would expect to find. And I'm really sorry for any confusion that I probably caused here, guys. DD  ........ |

|

|

|

|

|

#39 |

|

Senior Member

Join Date: Dec 2010

Location: East Coast in CT

Posts: 1,529

|

V8COOPMAN you have once again taken the time to illustrate actual facts I Thank You for that. ARP Ultra Torque is by far the best product for those of us who prefer accuracy where Torque is required.

Of course there's going to be individuals who would never consider spending money for such a product. The main reason COST I can hear it now can be done for less using such and such instead. Ronnieroadster

__________________

I use the F word a lot no not that word these words Flathead , Focus and Finish. "Life Member of the Bonneville 200 MPH Club using a Ford Flathead block" Owner , Builder, Driver of the First Ford Flathead bodied roadster to run 200 MPH Record July 13, 2018 LTA timing association 200.921 in one and a half miles burning gasoline. First ever gas burning Ford flathead powered roadster to run 200 MPH at Bonneville Salt Flats setting the record August 7th 2021 at 205.744 MPH |

|

|

|

|

|

#40 |

|

Senior Member

Join Date: Oct 2019

Location: Carthage , Tennessee

Posts: 199

|

That is an excellent chart and graph .

What is Detroit #2,,,,,,and I see where the graph converged at torque cycle 8 ,,,on oil and ARP ultra torque . Good reading . Tommy |

|

|

|

|

|

#41 | |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,114

|

Quote:

https://arp-bolts.com/p/arpultratorque.php |

|

|

|

|

|

|

#42 | |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,114

|

Quote:

I appreciate that, Ron! DD |

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

Hey my comments are not a dig on ARP bolts. They are a very good bolt. When I was swapping out a yblock on my 57 I took an idea of using grade 8 bolts from the hardware store to put in the clutchplate. I shortly came to my senses and bought some ARP shouldered flywheel bolts. No I'm not concerned about using ford bolts or other suppliers, within reason.

But to say you can always torque within 5lbs is interesting. My last tourque wrench was 300$ 100-300# Changed out my brothers new truck wheel bearings. Last edited by Tinker; 03-22-2021 at 10:32 PM. |

|

|

|

|

|

#44 |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,114

|

PERCENT...! Not POUNDS!! PER-%-CENT!!! DD |

|

|

|

|

|

#45 |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

Didn't answer how you calibrate your torque wrenches. Last I recall torque settings are units of foot-pounds. It doesn't matter. I was just asking as I don't know and hoped you can help.

Last edited by Tinker; 03-23-2021 at 01:59 AM. |

|

|

|

|

|

#46 |

|

Senior Member

Join Date: May 2010

Location: Auburn, MA

Posts: 2,106

|

Sponsored Links (Register now to hide all advertisements)

__________________

“The technique of infamy is to start two lies at once and get people arguing heatedly over which is true.” ~ Ezra Pound |

|

|

|

|

|

#47 | |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

Quote:

Too pull teeth or to put a foot in a pound of mouth. Always best too not take the time to educate. Okay that makes sense, frank. thanks, i wonder if I use old bolts and they can take it, granted my flathead is not going down a runway... have I made a mistake. https://www.enginelabs.com/news/torq...ot-pounds-one/ I'm still asking about calibration of torque wrenches also. . Last edited by Tinker; 03-25-2021 at 01:17 AM. |

|

|

|

|

|

|

#48 |

|

Senior Member

Join Date: Aug 2018

Location: Ottawa, ON

Posts: 855

|

That is an excellent article. Even as a mech eng I learned something. A Gr 8 bolt is a Gr 8 bolt no matter who makes it. This of course assumes manufacturers abide by recognized standards and quality control procedures. As such, an ARP Gr 8 bolt is no better than anyone else’s Gr 8 bolt although they may look prettier.

|

|

|

|

|

|

#49 |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

No article included on your post. I'm not sure that is true. also grade 8 bolts are brittle and don't give to sheer. Just saying.

|

|

|

|

|

|

#50 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,181

|

Quote:

This of course assumes manufacturers abide by recognized standards and quality control procedures. This can be a big assumption. There are a number of articles that test hardware store grade 8 bolts have been proven to really be around grade 5 or less. Just because it’s gold in color, doesn’t mean it’s an accurate grade 8 bolt. Last edited by Tim Ayers; 03-25-2021 at 06:28 AM. |

|

|

|

|

|

|

#51 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,068

|

ARP head and main studs are not Grade 8 - lets start there. Their tensile strength is roughly 190,000 PSI (depending on the application and material) - Grade 8 is around 150,000. But, there is a lot more to it than just the grade - consider material, material sources, manufacturing processes, thread design, heat treating, etc.. ARP studs have rolled threads - you won't find those when you go to Tractor Supply and buy Grade 8 bolts.

By no means am I saying that every flathead needs ARP hardware (I am not in Sales!), but there are many differences between regular Grade 8 bolts (and who knows where they are manufactured, what type of materials, what processes, etc), vs ARP hardware. Here are a couple links in case you're bored: https://arp-bolts.com/p/technical.php https://www.hotrod.com/articles/why-use-arp-bolts/ |

|

|

|

|

|

#52 |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,181

|

Taken from the article B&S's posted.

Simply stated it comes down to quality, both of the materials used and the process of making the various fasteners. Everything is made in the United States, and ARP always uses top-shelf materials. For example, take the ever-popular 8740 chrome moly steel. It comes from the mill in four different grades. The lowest grade is commercial, followed by aircraft-quality. ARP, however, only uses the top two grades (SDF and CHQ). These grades cost twice as much, but it's why they have a reputation for "zero defect" quality. In short, not all 8740 steel is the same, and this is why an 8740 fastener from ARP will cost you more than a Brand X fastener even if it also states it's 8740. Take from article to support my point regarding overall machining quality: For example, when ARP makes 12-point hex nuts, its process with the automated threading equipment turns out a nut with an accuracy of 0.001 inch! That's five times higher than the aerospace standard. It also means there'll be a perfect fit between the bolt/stud and the nut. |

|

|

|

|

|

#53 |

|

Senior Member

Join Date: May 2010

Location: Auburn, MA

Posts: 2,106

|

It's kind of like running a nut up and down a 10-32 screw. It seems to fit pretty good and will do the job. Now screw a micrometer - 40 threads per inch - and feel the difference in a precision machined screw.

The question is how much is really needed? The answer depends on what margin of safety you want to run.

__________________

“The technique of infamy is to start two lies at once and get people arguing heatedly over which is true.” ~ Ezra Pound |

|

|

|

|

|

#54 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,068

|

|

|

|

|

|

|

#55 | |

|

Senior Member

Join Date: Aug 2018

Location: Ottawa, ON

Posts: 855

|

Quote:

|

|

|

|

|

|

|

#56 |

|

Senior Member

Join Date: May 2013

Location: Pa.

Posts: 2,174

|

JM2 cents! I gotta go with Ol’ Ron on this! He’s built a boat load of engines so while it is his opinion it’s VERY EXPERIENCED opinion! I have only had & worked on 1 Ford Flathead (1949) 8BA), I have built or torn down for repair probably 100 mixed Mfgr engines, all overhead valve type. To say ARP are the best probably true. If ur building a sponsored race car or got the green w/o a sponsor & racing every weekend where the costs are secondary to safety & breakdown due to very over top extreme repetitive conditions, then absolutely buy ARP! To say a bit more expensive is a misnomer! I’ve never used ARP as I could buy a good running used engine for the price of a set of ARP head bolts. I always used new OE hardware where strength mattered from reputable Auto Parts stores @ 20% of the cost of ARP’s hardware. Also never had a Hardware failure on any I worked on. OK, that is just opinion from me. a nobody but I can’t think of any auto mfgr’s who use ARP in their vehicles (I may be wrong on special order Perf cars like Shelby Mustangs for obvious (race car) reasons! Hey it’s a free country so far so if cost isn’t a factor go for it

__________________

Nomad Last edited by AnthonyG; 03-25-2021 at 11:28 AM. |

|

|

|

|

|

#57 |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,409

|

There is no better feeling than being able to buy beer for the crew after you win and you don't win with second hand oats.

|

|

|

|

|

|

#58 |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,181

|

Everyone is basing price on the Speedway catalog. They do not cost $550. I will try to find my receipt from Allen’s fasteners

|

|

|

|

|

|

#59 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,068

|

The head stud kits that cost $550 include their high-strength stainless alloy solid acorn nuts. These are made from very expensive material. There are the parts that drive the price way up.

If you want real acorns that don't rust - these are the ones to have . . . but you'll pay for them. They're a real nice product - but not necessary in the least - unless you're looking for the 'bling' factor. B&S |

|

|

|

|

|

#60 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,860

|

What do you torque these $550 studs to? Are you aware of the facte that the block is only 1/4-3/8 thick in some places. The reason I torque the heads to 45 ft/lbs is to prevent warping the block. I do this for several heat cycles to normalize the the clamping force over the intire area of the block/head combination. Even in a blown engine, the studs/bolts are not the issue, and the stock studs/bolts will work just fine. However, I could be wrong!! so buy them, you'll feel better,

|

|

|

|

|

|

#61 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

First off, the studs do not cost $550. Second, the issue is more the true fit into the heads, not the ultimate strength!

|

|

|

|

|

|

#62 | |

|

Senior Member

Join Date: Sep 2014

Location: Wiscasset, Maine

Posts: 1,981

|

Quote:

Yes, we're on the same page about this! Good reply too. Glenn |

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#63 |

|

Senior Member

Join Date: May 2010

Location: MN

Posts: 7,053

|

Well good thing about youtube I guess, is videos about calibrating torque wrenches. Lot of different videos.

https://www.youtube.com/watch?v=1GrA5q_eu1k . |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 04:16 PM.

Linear Mode

Linear Mode