|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#2 |

|

Member

Join Date: Nov 2012

Posts: 45

|

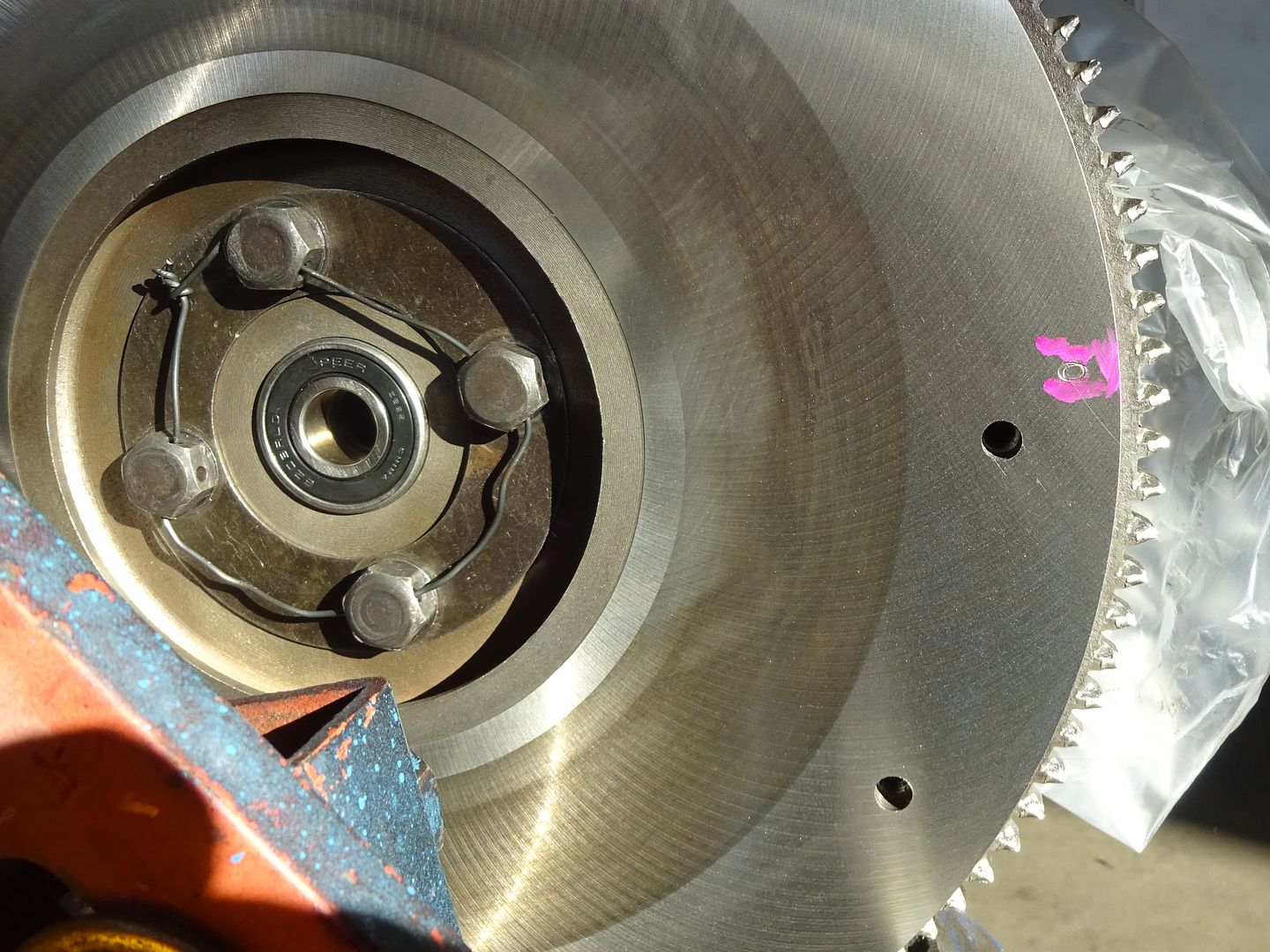

Hardware bolts longer then oem bolts

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Coral Springs FL

Posts: 10,919

|

Old Henry, Would it be possible to remove one opf those

bolts and compare it to an OEM bolt? Is the clutch disk facing the wrong way? |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Napa,California

Posts: 6,029

|

Looks to me like the clutch facing is severely worn which allows the springs to get close to the bolts. Did it just start doing this? The bolts look correct(OEM) with the safety wire.

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: on the Littlefield

Posts: 6,156

|

it could be that the flywheel has been resurfaced too much, it also could be the clutch disc is not the same as original ford one, thicker there---or a combination of both

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Nov 2010

Location: NM

Posts: 2,438

|

Sponsored Links (Register now to hide all advertisements)

(beat me, Kurt!)

__________________

'52 F-1, EAB flathead |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: NorCal

Posts: 2,617

|

Are there washers under the bolts?

|

|

|

|

|

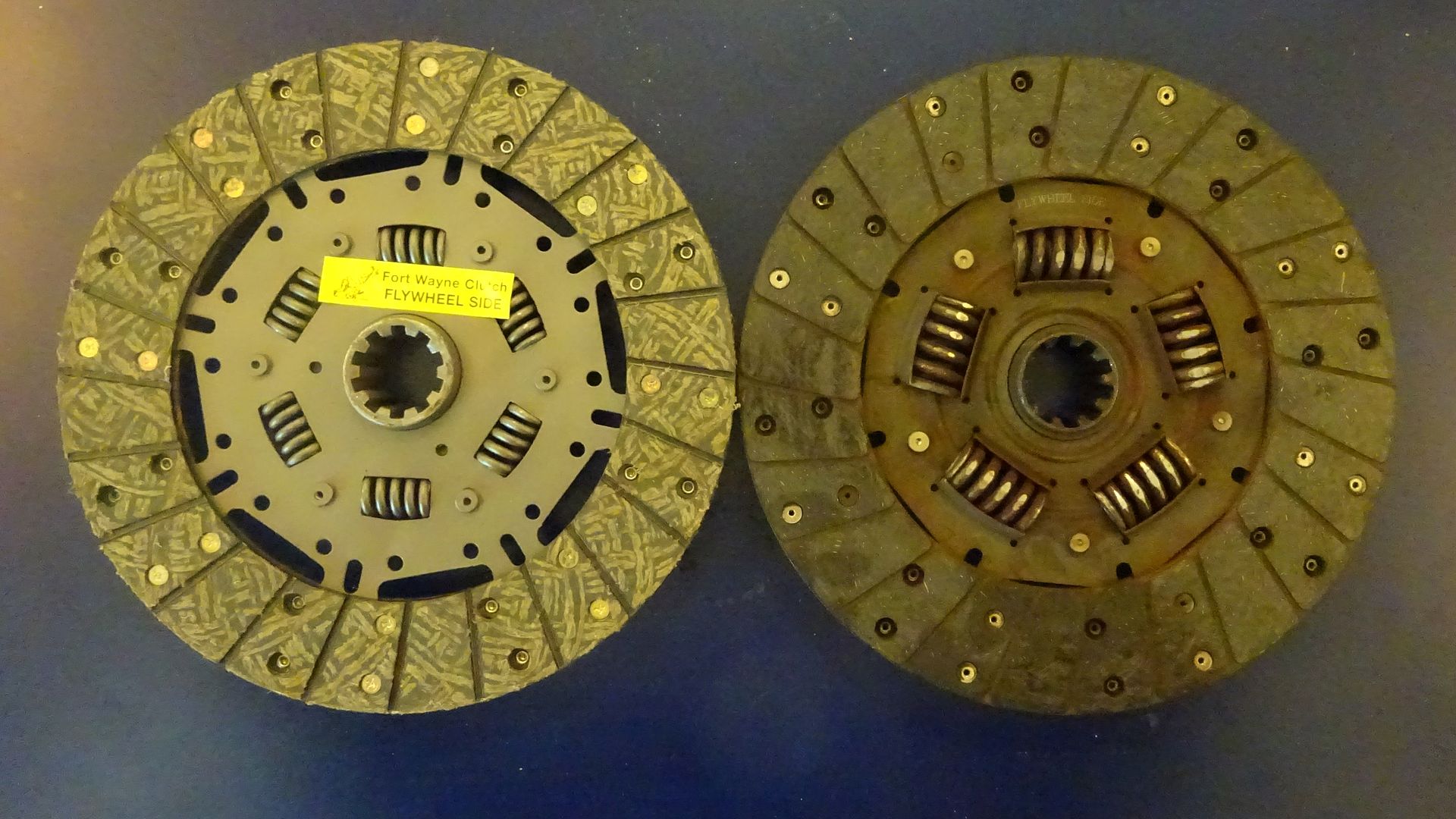

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Near Rising Sun, Maryland

Posts: 10,858

|

Looks like you might have lock or flat washers under those bolt heads, and if so, they should not be there. Or they could be marks made by a socket or the underside of the bolt heads when bolts were tightened.

Looks like Kahuna may have beaten me to the punch on the washer theory  Probably not part of this particular problem, but looks like excessive fretting corrosion on ID of pilot bearing. Also wondereing if there is damage on the small diameter of the transmission input shaft that goes into that pilot bearing ID? Might be worth checking that out, and also the pilot bearing itself before you put this car back together. I'm sure if Mac VanPelt is going through this transmission, he will check the pilot diameter on the input shaft. Would be interesting to know what else he finds on this transmission

__________________

John "Never give up on what you really want to do. The person with big dreams is more powerful than one with all the facts". Albert Einstein Last edited by JM 35 Sedan; 04-03-2017 at 10:38 AM. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: East Hartford, Ct

Posts: 5,898

|

__________________

DON'T RECALL DOING SOMETHING FOR MYSELF BASED ON SOMEONE ELSE'S LIKES OR DISLIKES |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Location: Wisconsin, USA

Posts: 8,988

|

Bingo!

__________________

"I can explain it for you. However, I can't understand it for you". |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jan 2011

Location: sw minnesota

Posts: 4,567

|

i bought a new disk a while back that was about 060 thinner than it should be. ebay junk

|

|

|

|

|

|

#12 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

If you look at the face of the clutch you can see that the rivets which hold the clutch material onto the disk have been rubbing on the flywheel as well. A new clutch plate is required.

Last edited by JSeery; 04-02-2017 at 12:52 PM. |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: Near Rising Sun, Maryland

Posts: 10,858

|

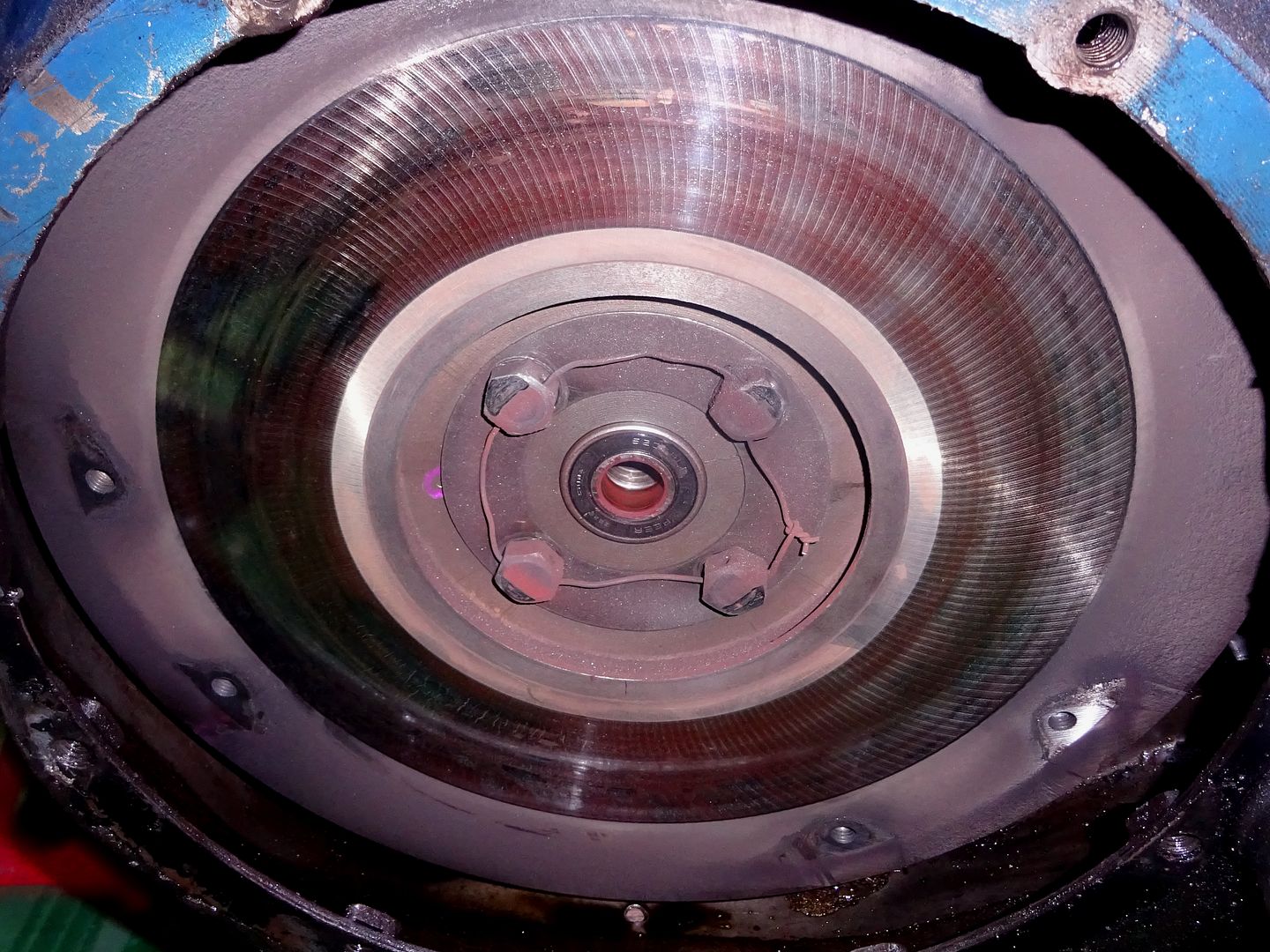

I agree, and also think the clutch face surface finish on the flywheel appears to have a coarse cut finish which may have eaten that clutch disk material very quickly. A lot of things appear to have been going wrong here at the same time.

__________________

John "Never give up on what you really want to do. The person with big dreams is more powerful than one with all the facts". Albert Einstein |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Thanks for all responses.

This clutch only has 38,000 miles on it but am replacing it while tranny is out being rebuilt by VanPelt. The rivets that look like they have rubbed on the flywheel are actually still below the surface of the clutch although just barely. Don't know why they look like that. Flywheel bolts are the original. Don't have any washers under them. I agree that it is most likely a combination of worn clutch and over-machined flywheel. Will definitely replace clutch and consider replacing flywheel.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#15 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Not a welcome outcome I'm sure, but I agree 100%. As much as you drive the car it is going to need a new flywheel before long.

|

|

|

|

|

|

#16 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

I got this clutch from Fort Wayne Clutch so thought it would last longer than 38,000 miles. If there is any better source out there I'd like to hear it.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#17 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Think the issue may be the surface of the flywheel and not the clutch material itself. The flywheel appears to have a very rough cut surface that will eat up any clutch plate.

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Location: pittsfield, MA

Posts: 2,086

|

Professor, When you get it all figured out and re-assembled, have a guy who knows how to wrap safety wire do it.

John |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

I know the surface looks like a rasp but it's as smooth as any flywheel surface. It's just the way the light plays on the machining marks that makes it look rough.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

If there was anyone around that knows how to wrap safety wire I'd have them do the whole job. There isn't. So, how do you do it? It will be me doing it if I replace the flywheel. A picture of correct wiring would be most helpful.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-02-2017 at 05:18 PM. |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: May 2010

Location: East Hartford, Ct

Posts: 5,898

|

Probably the way yours is done is the same way Ford did it on hundreds of thousands of cars without any issues.

__________________

DON'T RECALL DOING SOMETHING FOR MYSELF BASED ON SOMEONE ELSE'S LIKES OR DISLIKES |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,743

|

The clutch would have (some) more life in it if the springs had not been touching the bolts.

The flywheel might be smooth now but maybe it wasn't so smooth when first fitted. You can do a few things, amongst which may be: You could simply fit another clutch which will last at least 38,000 miles. Maybe more if the flywheel smoother now than it was when new scenario is true. Lets say 40,000 miles as a guess. You could skim a few thou off the heads of the bolts. if you take .040" off, they should still be perfectly serviceable and would extend the life of the next clutch. I don't know, lets say 60,000 miles. The above scenarios would not involve removal of the flywheel or more importantly (if the engine is still in the car) the pan. If you can find a good condition, useable as is 59a type flywheel and fit that, without it having to be skimmed, you will get the maximum life from your clutch. I don't know what can be expected, would 60,000 miles be normal? It's a heavy car and gets driven over demanding roads. It would last indefinitely if driven on freeways all the time. If you find a flywheel and it can be made serviceable with just the lightest skim, the life should be as above, as long as the skim is not excessive, as it does seem reasonable that is what has caused the premature spring/bolt contact above. I wouldn't worry about the bolts wiring too much. If they are torqued correctly, the wiring should never be called upon to stop them loosening. I found better success using thinner wire on the last job I did, but it still came up far short of some of the illustrations I have seen. Hope the above helps in some way. Long story short, find a better flywheel. I just had a thought, did you say you had that one balanced? If that is the case one of the first two options may appeal more. Mart. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

All good ideas to be considered, Mart.

I agree that the flywheel surface is smoother now than when last resurfaced. That makes me hesitant to get a new one that would likely have the rougher new surface. I don't mind a bit grinding off some of the bolt heads and had thought about that. My biggest concern is that this clutch has had bad chatter since it was put in new with the newly surfaced flywheel 38,000 miles ago. I'd really like to lose that for a time if not for good. I know I've got to replace the clutch but wonder which way my chances of losing the clutch chatter would be better, keeping the flywheel I have with the worn down but smooth surface or get a new one with a new rougher surface. That's the "$64,000 question" (a popular TV quiz show here in the states back in the 50's).

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-02-2017 at 08:40 PM. |

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Location: pittsfield, MA

Posts: 2,086

|

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Now that right there is just downright purty.

But, it looks a lot more like a modern motorcycle brake rotor than a vintage Ford flywheel.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-02-2017 at 08:37 PM. |

|

|

|

|

|

#26 |

|

Senior Member

Join Date: Oct 2011

Location: Shelton, WA

Posts: 3,799

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#27 |

|

Senior Member

Join Date: May 2010

Location: now Kuna, Idaho

Posts: 3,778

|

I see some heat checks and hot spots in the flywheel, probably a result of Ol' Henry being stuck a few times. This could lead to chatter, possibly. Surface of disc and flywheel could be heat glazed. More chatter. Does the disc have proper marcel? This is the "springiness" of the disc, looking at the edge. The metal that the lining is riveted to should be wavy, slightly separating the two linings. This provides a cushion as the clutch engages and squeezes the disc together gradually instead of grabbing all at once.

|

|

|

|

|

|

#28 |

|

Senior Member

Join Date: May 2010

Location: Coral Springs FL

Posts: 10,919

|

I doubt that Henry Ford would allow his "worker" to take the time to correctly install safety wire.

|

|

|

|

|

|

#29 |

|

Senior Member

Join Date: Mar 2015

Location: Acworth GA

Posts: 534

|

Safety wiring is a technique to keep a bolt from unscrewing itself and causing damage. Safety wire is NOT meant to keep the bolt tight, the proper installation torque is what keeps the bolt tight (assuming the bolted joint is correctly designed). I'm sure rotorwrench has a comment about this.

The stock Ford loop of wire through the flywheel bolts is almost useless, IMHO, as is safety wiring/cotter pinning connecting rod bolts/nuts. These are types of joints which, if they come loose, part destruction will occur before the machine can be stopped. The wire will not maintain the bolt at a proper torque, it just keeps it from fouling the rest of the machine if for some reason the threaded connection comes loose. There is a lot of online info about safety wiring practices in aviation. Aircraft procedures have been adopted in most areas, like auto racing, where this kind of safety backup is required. A buddy once told me that for aviation or racing, the best stuff you can get is barely adequate. True, I think.

__________________

Houston, Tranquility base here. The Eagle has landed. |

|

|

|

|

|

#30 |

|

Senior Member

Join Date: May 2010

Location: CLAYTON DE

Posts: 1,282

|

You need a fresh start. Begin with condemning the flywheel. What does Mac VP offer as opinion. For me any flywheel that looks irregular and/or, has a history of being machined qualifies to either be used as a paper weight, hung on the wall, or turned in for scrap.

The fact that you have had to put up with clutch chatter says it all for me. If there were not a history of being previously cut and trouble with clearance. I would try some chemical cleaner to remove what has to be burnt gum-glaze build up. (given that you say it is smooth) That pattern is real and is the place that chatter develops and grows. Get picture of surface to Ft Wayne or Mac. Kurt in NJ, Ross F-1, Kube, JM 35, Mart, Jseery, 40 Deluxe, will not argue with replacing flywheel. Good luck.

__________________

Enjoy yer day. Tom  Hate can't fix what it started. Last edited by A bones; 04-03-2017 at 06:00 PM. Reason: proof read |

|

|

|

|

|

#31 |

|

Senior Member

Join Date: Jun 2014

Location: Williamsburg, VA

Posts: 1,627

|

Don't have a real picture, so try this: Picture a flywheel bolt trying to unscrew itself; then run the safety wire to the adjacent bolts in a way that would most strongly oppose that unscrewing. It will will end up in a four blade saw tooth pattern.

|

|

|

|

|

|

#32 | |

|

Senior Member

Join Date: May 2010

Location: pittsfield, MA

Posts: 2,086

|

Quote:

The assembler who installed the flywheel could correctly safety wire the bolts in 20 seconds or less. John |

|

|

|

|

|

|

#33 |

|

Senior Member

Join Date: Feb 2011

Location: Buchanan, MI

Posts: 676

|

Four things I would do.

Get rid of the dowel retaining ring. Get rid of the lock-washers. Maybe trim the bolt heads a fuzz. Use red locktite to retain the bolts. No reasonably modern engine uses the plate & safety wire. I don't care how Ford did it. Simply not needed. I deal a lot with mid fifty's Cadillacs, they don't use that stuff & they stay together. |

|

|

|

|

|

#34 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#35 | |

|

Senior Member

Join Date: May 2010

Location: East Hartford, Ct

Posts: 5,898

|

Quote:

Removing it will allow the bolts to move closer to the flywheel. Some have been assuming that they see lock washers under the bolts. ( I don't see any )

__________________

DON'T RECALL DOING SOMETHING FOR MYSELF BASED ON SOMEONE ELSE'S LIKES OR DISLIKES |

|

|

|

|

|

|

#36 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

Most folks reuse the bolt ring since it just acts as a washer for all four bolts that cant turn when you tighten up the bolts. It probably has scratches from multiple removal/installation. If that ring has to go than the flywheel really should go. Stuff does wear out and compensating for wear by removal of key parts is just asking for more trouble. In the 8BA years, Ford did away with the thick headed bolts and safety wire for stronger cupped head bolts and they don't have any history of backing out that I'm aware of.

|

|

|

|

|

|

#37 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

The bolts aren't too long to remove that big washer? They'll still tighten OK?

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#38 |

|

Senior Member

Join Date: May 2010

Location: East Hartford, Ct

Posts: 5,898

|

Measure the bolt fit (length) to the threaded hole and if necessary remove material from the threaded end.

__________________

DON'T RECALL DOING SOMETHING FOR MYSELF BASED ON SOMEONE ELSE'S LIKES OR DISLIKES |

|

|

|

|

|

#39 |

|

Senior Member

Join Date: Nov 2010

Location: NM

Posts: 2,438

|

8BAs aren't safety-wired, I wonder if their bolts are enough shorter to gain what you need? Sure, the flywheel is near end-of life, but it's a big deal to replace and driving season is coming up quickly (although that's a year-round season for you!)

__________________

'52 F-1, EAB flathead |

|

|

|

|

|

#40 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,743

|

I wouldn't delete the plate. It acts as an anti stress raiser for the cast iron flywheel. I would consider using an alternative bolt from another motor that has a washer face built in and less overall height. If they were available I would then consider deleting the plate, but would possibly stake the dowel holes so the dowels can't come out (Unlikely, I guess).

I saw a flywheel explode on a test cell, due to the use of Allen bolts instead of regular bolts holding it on. The smaller head of the allen bolt created too much stress and the flywheel exploded. There was a big dent in the roof girder from the shrapnel. This is why I would leave the flat plate in place, unless using washered bolts. Mart. |

|

|

|

|

|

#41 | |

|

Senior Member

Join Date: Feb 2011

Location: Buchanan, MI

Posts: 676

|

Quote:

There are about a zillion small block Chevys with cast iron flywheels & non washered bolts on the road at any given time. Don't over think it. |

|

|

|

|

|

|

#42 |

|

Senior Member

Join Date: May 2010

Location: Auburn, MA

Posts: 2,106

|

Allow me to throw another wrench into the works. As far as clutch chatter, is the flywheel running true to the block? The transmission is being rebuilt and I think I have heard of worn bearings being a factor. Then again just having the disc rubbing against the bolts during engagement could have been an issue. It would be interesting to measure your flywheel against a known good one or one not resurfaced. I don't have a ton of experience but this seems like an unusual issue as a flywheel will not be resurfaced many times like a brake drum.

__________________

The technique of infamy is to start two lies at once and get people arguing heatedly over which is true. ~ Ezra Pound |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 |

|

Senior Member

Join Date: May 2010

Location: CLAYTON DE

Posts: 1,282

|

Please help me understand why. Nuts and bolts, The chatter will be gone.

__________________

Enjoy yer day. Tom  Hate can't fix what it started. |

|

|

|

|

|

#44 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,743

|

^^ I think purely because flywheel replacement means pan removal and may also mean engine out. Other than that, as you say, just nuts and bolts like everything else. Compared to just putting a new clutch disc is, it's a much bigger job.

Mart. |

|

|

|

|

|

#45 |

|

Senior Member

Join Date: May 2010

Location: Granger (Northern) Indiana

Posts: 1,520

|

JFYI, I am using flywheel bolts from ARP that have a shorter head for more disc spring clearance on an 8BA. The part number is P10AP.750-1 and are 7/16" x 20 x .750", 3/4 hex, .250 shank, .250 head.

|

|

|

|

|

|

#46 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Sponsored Links (Register now to hide all advertisements)

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#47 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-04-2017 at 10:47 AM. |

|

|

|

|

|

|

#48 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

And, NAPA doesn't just have those flywheels piled up on their shelf. Mac VanPelt is checking to see if he has one any better than mine. They do not appear to be readily available, certainly not new from the usual suppliers that I have checked. Repops on ebay are upwards of $400.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#49 | |

|

Senior Member

Join Date: May 2010

Location: Granger (Northern) Indiana

Posts: 1,520

|

Quote:

70 ft/lbs with moly 75 ft/lbs with locktight 85 ft/lbs with oil. I did not use the dowel retainer just to gain another .050" or so. I'm using a steel Centerforce flywheel that cost well below $400, but that was a few years ago. Last edited by V8 Bob; 04-05-2017 at 06:59 AM. |

|

|

|

|

|

|

#50 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

What is chamfer?

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#51 |

|

Senior Member

Join Date: May 2010

Location: Granger (Northern) Indiana

Posts: 1,520

|

|

|

|

|

|

|

#52 |

|

Senior Member

Join Date: May 2010

Location: now Kuna, Idaho

Posts: 3,778

|

I think he means a slight countersink on the flywheel bolt holes so the radius under the bolt head doesn't contact the edge of the bolt hole.

Also, try setting up a dial indicator on the bell housing to measure any runout on the flywheel face. I once ran into a flywheel that was not true. Apparently the guy who resurfaced it was careless somehow so that the flywheel was not flat in his machine and was cut crooked. |

|

|

|

|

|

#53 |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,106

|

In this situation, chamfering a hole is similar to barely touching the top of the hole with a counter sink. The main reason is to make a relief space at that SHARP 90 degree angle when a hole is drilled. The space is necessary because MOST bolts have a radius of material just below the head, where it transitions into the shank. Without the chamfer, the bolt HEAD would not actually sit flush with the FLAT surface. DD

|

|

|

|

|

|

#54 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

I wonder what kind of machine was used to resurface that flywheel? There were some really good machines that were dedicated just for flywheels but there are other ways that don't leave quite as nice a finish and possibly not as accurate a surface thickness/concentricity depending on machine and/or operator.

|

|

|

|

|

|

#55 | |

|

Senior Member

Join Date: May 2010

Location: Near Rising Sun, Maryland

Posts: 10,858

|

Quote:

__________________

John "Never give up on what you really want to do. The person with big dreams is more powerful than one with all the facts". Albert Einstein |

|

|

|

|

|

|

#56 | |

|

Senior Member

Join Date: May 2010

Location: Granger (Northern) Indiana

Posts: 1,520

|

Quote:

I caused some confusion by stating "flywheel bolt threads" on an earlier thread, but should have said "flywheel bolt holes" which has been corrected. The 4 flywheel bolt mounting holes need to be chamfered. Last edited by V8 Bob; 04-05-2017 at 07:07 AM. |

|

|

|

|

|

|

#57 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

If the shatter started after the flywheel was resurfaced there΄s a chance the machine/machinist did a less good job and the surface ain΄t running true to the crank now.

I΄ve seen so many flywheels come into the shop that΄s been freshly machined by lathes or grinders but way off in the surface... Next source would be soft engine mounts and when the new clutch got a better grip it managed to move the engine more then the old one ? |

|

|

|

|

|

#58 | |

|

Senior Member

Join Date: May 2013

Location: Pa.

Posts: 2,163

|

Quote:

Prof., I think I have a re-surfaced flywheel that originally I tried to use with a10.5" or 11" clutch but someone had tried to re-drill / tap for larger clutch on a flywheel originally used for a 9" clutch and drilled the holes almost .100" out of concentric. The 9" pattern is good. I'll get some pic's of it and check the size of the bolt circle too make sure and I'll PM you.

__________________

Nomad |

|

|

|

|

|

|

#59 |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,106

|

Anthony.........If that flywheel is for your 8BA, it won't work on Craig's early block. Just sayin'! DD

|

|

|

|

|

|

#60 |

|

Senior Member

Join Date: May 2013

Location: Pa.

Posts: 2,163

|

DD, thx, my knowledge only goes as far as my vehicle and what I learned / read on the Barn with regard to the Early Fords. If it wasn't for your help and others here I'd of been up the creek quite a few times while building my '35 with as you indicate a '49 8BA. I do bow to the more experienced guys on the site who have much more breadth of knowledge than I. Turned out I remembered wrong, memory not what it used to be, LOL. Checked my records and forgot Jerry Livingston, United Engines who built my motor took back the flywheel I thought I still had and sent me another. I gave the Prof. a heads up in a PM.

__________________

Nomad |

|

|

|

|

|

#61 |

|

Senior Member

|

I fitted a new clutch and PP( Imported ) after running it a while it developed some chatter ,I have Borg and beck setting jig so I set it up and found the fingers were not even ,I suspect the re popped clutches don't use hardened pins in the arms so something had worn .the clutch smoothed out on replacing it so having the finger s even is important ,just a few thou. In the light of that on a old ford clutch if the thrust bearing and it mechanism does not release the three fingers evenly then that may be a contributing factor, Ted

|

|

|

|

|

|

#62 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Fortunately, clutch chatter doesn't interfere with me driving my flathead over ten-thousand miles a year and most likely never will.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-04-2017 at 08:01 PM. |

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#63 |

|

Senior Member

Join Date: May 2010

Location: san antonio, texas

Posts: 461

|

|

|

|

|

|

|

#64 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Whew, mine isn't that bad. Whew, mine isn't that bad.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-04-2017 at 11:32 PM. |

|

|

|

|

|

|

#65 | |

|

Senior Member

Join Date: Nov 2010

Location: NM

Posts: 2,438

|

Quote:

__________________

'52 F-1, EAB flathead |

|

|

|

|

|

|

#66 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Sponsored Links (Register now to hide all advertisements)

The flywheel was surfaced by the local racing machine shop, the same one that balanced every moving part in my engine that makes it run so smooth now. It doesn't look quite as bad in this light as the first picture on this post. It certainly was never as rough as the first picture looks and is smoother now than when first surfaced 38,000 miles ago. As far as I know, that was only the second time it had been surfaced. (The very slight wear shown is from the very brief driving of the car after the engine was first rebuilt but not balanced and had a bad vibration and had to be removed, dismantled, and balanced.)

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-04-2017 at 10:13 PM. |

|

|

|

|

|

#67 |

|

Senior Member

Join Date: Jan 2011

Location: sw minnesota

Posts: 4,567

|

long thread here! no one has pointed out the obvious here, the center plate holding the springs has wear too. certainly thats gonna have some effect, chatter-noise-somthing was going on near the end. 38000 miles, and always chatter? from day one? anti chatter rods tight to the frame? they are a bugger when the threads are bad or if you dont have the right size tool to tighten them. its a bastard size, not a 3/8 square, and bigger than a quarter. i made a tool on the mill and it lasted one bolt and was junk-too soft. next one i had to weld the head to the frame to get the nut off, then grind of the weld to get the bolt out. now, i order grade 8 allen heads from fastenal. so, are your bolts tight? next, flywheel surface. i have used flywheels that sat out side for decades and cleaned them up with 80 grit on a sander. never had a problem, unless it was obvious once the surface was clean. next is the issue of the disk center hitting the bolts. its from ft wayne, we'd all like to say its good, but if you still have another disk laying around, i'd like to know the distance from the hub to the spring cage that was hitting the flywheel. it could be a bad part. not ruled out yet. i'd take a grinder to the bolts if the distance is correct. next, clutch chatter can also come from other worn out parts. u joint would be obvious, you are there now, worn spline? bad front drive shaft bearing or thrust washer?, sheared pin on the rear coupler? also, as mentioned, it would be easy to check the runout of the flywheel, on the car. many crank grinders do not face that off unless you ask them to check it. i am not the expert here just maybe brought up some other points. i know you do lots of miles, bless you for that, i drive the heck out of my cars too. love your travel photos, and hows the new dog doing without a car to ride in? best wishes, skip

|

|

|

|

|

|

#68 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

No anti-chatter rods on a '47.

Dog has wife's RAV4 to ride in that she likes even better.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#69 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

The surface doesn΄t look bad just so that it runs true, if it΄s a machineshop building race engines they should know how to surface a flywheel.

I would look at the condition of the engine and gearbox mounts if they are soft or not tight you get shatter to. |

|

|

|

|

|

#70 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

|

|

|

|

|

|

#71 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

If the shop doing the flywheel doesn't have a rig like this then you have to be aware. Watch the video of the machine in action. You can see how bad a flywheel can get.

http://www.winonavannorman.com/produ...g5000_flywheel |

|

|

|

|

|

#72 |

|

Senior Member

Join Date: Jan 2011

Location: sw minnesota

Posts: 4,567

|

well heck no wonder if you dont have chatter rods!, just kidding, i thought they went up to the shoebox. when is the end of the rods? thanks for the education i always get here!!

|

|

|

|

|

|

#73 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

You can cut a flywheel on a lathe...if...there is no hardspots...or...you cut thrue them.

Only time a flywheel meets a lathe here is when they are on a diet...loosing half there weight. |

|

|

|

|

|

#74 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

A lathe will certainly true them up but a grinder leaves a more conducive friction surface. Sort of like the cross hatch on a cylinder wall makes for better piston ring bedding in.

|

|

|

|

|

|

#75 | |

|

Senior Member

Join Date: May 2013

Location: Pa.

Posts: 2,163

|

The Flywheel grinding machine shown in the video looks a lot like a miniature version of machine I had to learn to run as a Tool and Die Apprentice called a Blanchard Grinder

Quote:

__________________

Nomad |

|

|

|

|

|

|

#76 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

Blanchard grinders can get a way lot bigger than a flywheel grinder but they both work on a very similar principle.

|

|

|

|

|

|

#77 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

Every new flywheel is just cut...the real reason you grind used flywheels are to deal with the hardspots.

|

|

|

|

|

|

#78 | |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,106

|

Quote:

http://www.fordbarn.com/forum/showth...=152238&page=2 .......which states: "Pressure plate and clutch were all replaced with new from Fort Wayne Clutch. It, along with the trueness of the crank just put in (it with the flywheel had less than 1/1000th run out whereas the previous crank was 2/1000ths) totally solved my clutch chatter problem I've suffered with for a year and a half. That was sure nice. I sure hope any redoing of the engine doesn't undo that nicety." I'm having a hard time understanding YOUR recollection of the clutch chatter. Back then you said the new clutch "totally solved my clutch chatter problem". Now, you state that this Ft. Wayne Clutch was bad from the start, 38K miles ago. Which is it? DD |

|

|

|

|

|

|

#79 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

Someone here must have a measurement for the depth,from flywheel clutch surface

to the flange surface that the bolts head seat on.That will determine what was removed from previous machine shops. The flywheel resurface was done on a grinder as the pattern is viable and not on a lathe. Run out must be taken to confirm it as square to the mounting surface. R |

|

|

|

|

|

#80 |

|

Senior Member

|

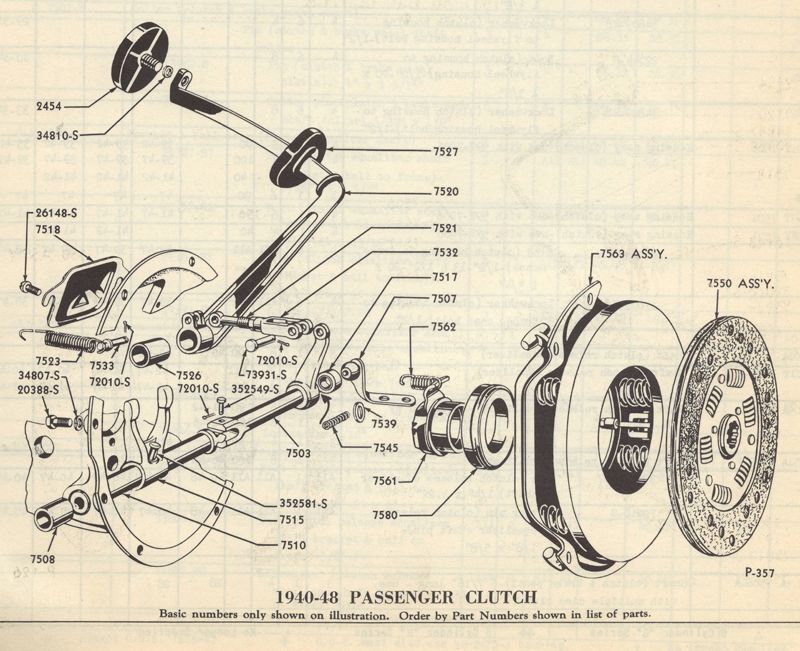

Heres the Borge setting jig it uses a 7mm spacer in three places to simulate the plate/disk, I think you could do the same with a venire on your fly wheel .the first pic is a diaphragm clutch that could be substituted for a ford one ,not sure of the brand .Ted

Last edited by FlatheadTed; 04-05-2017 at 08:52 PM. |

|

|

|

|

|

#81 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

"To get rid of my clutch chatter I resurfaced and balanced the fly wheel, replaced the clutch with one from Fort Wayne Clutch and balanced that. I even replaced the crankshaft to get rid of 2 thousandths of an inch run out. Clutch was smoother than it has been for years . . . for about 100 miles, then slowly returned to its pre-morbid state with the same chatter as before."

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#82 |

|

Junior Member

Join Date: Aug 2010

Posts: 15

|

I had the same issue one time after replacing with a new clutch. Later when removing the clutch again, I found the clutch disc was not uniform in thickness. I could see it with the naked eye. After replacing that disc, the clutch is now smooth.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#83 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

Ft Wayne clutch generally puts correct marcel spring plates and friction discs on there. The thirds world stuff, I'm not so sure.

|

|

|

|

|

|

#84 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

10 days and no fix wow!!!

Not the norm for "Old Henry" R |

|

|

|

|

|

#85 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Still waiting on VanPelt to finish my transmission and send it back to me.

I have the new clutch in from Fort Wayne clutch ready to install. I've decided that, since resurfacing the flywheel has not eliminated clutch chatter in the past, that I'm not going to do it this time nor replace the flywheel and just replace the clutch and hope for the best. The short headed bolts that V8 Bob recommended have no safety wire holes and the heads are not for standard socket wrenches.  Plus, they have that shaft under the heads that I think wouldn't work without doing some drilling on the flywheel and/or crankshaft. I am not confident enough to try that so won't. So, I'll just grind the stock bolt heads down a bit for when the new clutch wears down again its springs won't rub on them.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#86 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

Sponsored Links (Register now to hide all advertisements)

Just gently testfit them into the flywheel and see if they go in there nice ans smooth. |

|

|

|

|

|

#87 |

|

Senior Member

Join Date: Nov 2010

Location: NM

Posts: 2,438

|

The unthreaded shank under the head shouldn't be a problem at all, no grinding needed. Aren't the heads 12-point that a socket fits on? Those look like excellent bolts. Torqued down properly, no safety wire is necessary.

I agree on the flywheel machining.

__________________

'52 F-1, EAB flathead |

|

|

|

|

|

#88 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

I couldn't get any socket to fit on the bolt heads.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#89 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

They should be 12-point but I have no idea whether they are for the old Unified fractional sizes or for Metric sizes. 8BA engines use no safety wire but they do use the big ring washer to protect the flywheel surfaces around the bolt holes and close off the locating pin holes.

I'd check the condition of both front engine mounts and transmission mount at the rear. If they get spongy, the engine/tran can move forward a good bit when you let out on the clutch. If that happens, the equalizer gets off square and the clutch control effort is changed somewhat. |

|

|

|

|

|

#90 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,743

|

Try again, a standard 12 point socket should fit. The slightest chamfer on the flywheel holes should alleviate any worries about bolt to flywheel interference. The bolts shouldn't need to be a great fit because the flywheel is dowelled to the crank.

I'd use them. Mart. |

|

|

|

|

|

#91 |

|

Senior Member

Join Date: Sep 2011

Location: Black Hills, SD

Posts: 577

|

Just my 2 cents but I think flywheel resurfacing and turning drums just gets over done because we all think it's arbitrary to a good job. Personally, if a flywheel still looks smooth, I just take a coarse 3 inch scotchbrite roloc on a die grinder and and scuff/clean it up. Same on brake drums if they are bad grooved and measure ok. Ah, but you say they need trued. Well, it you think it's true, do the cut, remove the drum from the lathe, put it back in and you will see it is now taking off one side again before it's "true"

|

|

|

|

|

|

#92 |

|

Senior Member

Join Date: Sep 2011

Location: Black Hills, SD

Posts: 577

|

Quote:

Lots of flywheel bolts don't have safety wire or locking washers. Just use loctite. As I understand it, clutch chatter on an old Ford can come from lots of things since everything from the back tires to the fan is all one rigid unit. How about the chatter rods? Are they in place and proper? |

|

|

|

|

|

#93 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#94 |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,106

|

That bolt on the right obviously has all sorts of metallic dingleberries on the threads. Pretty obvious that the hole it came out of is in some stage of "stripping" it's threads. Another sign is the obvious FLATS on the "major" peaks of the threads. The threads inside that hole are well on the way to stripping at a most-inopportune time. In other words, you REALLY might want to think seriously about spending the bucks and get a decent flywheel on that thing. DD

|

|

|

|

|

|

#95 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#96 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Well the one on the right sure appears to have a problem. I would request a replacement.

|

|

|

|

|

|

#97 |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,106

|

Well if so, that possibly bodes well for the condition of your flywheel's threaded holes, but that bolt on the right is NOT a virgin. Where did those bolts come from? DD

|

|

|

|

|

|

#98 |

|

Senior Member

Join Date: May 2010

Location: Near Rising Sun, Maryland

Posts: 10,858

|

If I did nothing else to that flywheel, I would at least make sure it is mounting flat against the face of the crankshaft flange, and then check T.I.R. at the clutch face of the flywheel after it is bolted in place on the crankshaft. I would definitely want to know what was causing that chatter and rapid wear of the disc face before I put everything back in place.

__________________

John "Never give up on what you really want to do. The person with big dreams is more powerful than one with all the facts". Albert Einstein |

|

|

|

|

|

#99 |

|

Senior Member

Join Date: May 2010

Location: East Hartford, Ct

Posts: 5,898

|

Don't know what others are seeing but all I see is dust that will wipe off.

__________________

DON'T RECALL DOING SOMETHING FOR MYSELF BASED ON SOMEONE ELSE'S LIKES OR DISLIKES |

|

|

|

|

|

#100 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

If someone is referring to the little white stuff, yes, that's all it is, not metal filings as some may be supposing.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#101 |

|

Senior Member

|

Not sure if any one has considered this but When I restored my 35 I noticed the U joint torque tub moving under the clam ,so I packed over the ball with Teflon shims. Also Henry doesn't the 47 have a chatter rods going forward to the front cross member . its the same set up so what keeps it stable. Ted

|

|

|

|

|

|

#102 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#103 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

Rag lint on the threads. The threads appear to be rolled instead of cut. This is common for high strength fasteners.

They made kits back in the day that added a sort of anti-chatter capturing device from the bottom of the transmission to the frame. Folks have posted photographs of them on this forum but I haven't seen one for a while. Last edited by rotorwrench; 04-19-2017 at 05:23 PM. |

|

|

|

|

|

#104 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

Those appear to be arp bolts and covered in pocket lint. Nothing wrong with them.Blow them off with compressed air and install with loctite and you are good to go.They are a 12 point socket head.A 6 point socket will not fit.Walk into a local parts house and take the bolt with you and they will put the correct socket in your hands.Aircraft have ton's of 12 point bolts and nuts.A 12 point socket will also fit 6 point.This isn't rocket science.Be sure to use loctite and all is well.The shoulder on the bolt is required for the flywheel it will work.

R |

|

|

|

|

|

#105 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-19-2017 at 05:13 PM. |

|

|

|

|

|

|

#106 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

Sponsored Links (Register now to hide all advertisements)

R |

|

|

|

|

|

#107 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,855

|

It's been awhile since I worked on a 59 series engine. I've always thought that all engined had the plate under the flywheel bolts to retain the drive dowels. I've always used the late 8BA flwwheel bolts torqued to #70 lbs. I've never had a problem here. I know that the length of the bolt is critical, as it can hit the main bearing if too long. This may not be of any help, but just something to think about.

|

|

|

|

|

|

#108 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

I haven't removed my stock bolts yet. When I do, I'll compare them closely with the ARP bolts to see how they compare, then give it some more thought. I have a strong preference for stock unless there is some real compelling reason to replace with something else. I'm not sure this will be such a time.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#109 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

Those bolts have way more quality than your stock bolts and the stock ones were well designed as well.The arp mentioned are well utilized in high hp drag racing cars not a fire breathing 80 hp flat motor

The arp will cure the clutch plate interference if the head is thinner. The arp will cure the clutch plate interference if the head is thinner. R |

|

|

|

|

|

#110 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

That's why I like to stick with stock.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-19-2017 at 06:25 PM. |

|

|

|

|

|

|

#111 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Multiple choice quiz.

Which clutch disc is correct? A. A B. B C. A or B, doesn't matter. D. Neither are correct. Left disc, A, just received from Fort Wayne Clutch as replacement for Right disc, B, previously received from Ft. Wayne Clutch, just removed with springs rubbing on flywheel bolt heads.   Clue: Green Bible diagram of the clutch. Looks like a combination of the two. What do you think?

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 05-02-2017 at 12:19 AM. |

|

|

|

|

|

#112 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

You should be asking Ft. Wayne Clutch they will be way more informed on their product than the keyboard jockey's here.

R |

|

|

|

|

|

#113 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Unfortunately, both clutch discs were sent to me as correct from Ft. Wayne Clutch.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#114 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

If i had them in front of me I could confirm the one on the left in a heart beat.

It just needs a critical measurement and you are done.The one on the right when measured will give you the measurement that is much different.You still should make FT, W aware of the difference and get a response from the pic you show us.Just because they sent them to you doesn't make it correct.Talk to a tech guy there and have him walk you through it.I can see from the pic's there is more than one difference.Are both part numbers the same on your invoices? Were they the same price. What are the part numbers? R Last edited by Ronnie; 05-01-2017 at 07:46 PM. |

|

|

|

|

|

#115 |

|

Senior Member

Join Date: Oct 2013

Location: Glens Falls NY

Posts: 1,267

|

Old henry .... No anti-chatter rods on your '47 ?? My late '47 has them. Bell housing/frame have matching numbers.

|

|

|

|

|

|

#116 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

I have now looked at every clutch disc for the 47 passenger car that I could find on the internet from every source, including all the pictures I ever took of my previous clutch discs, and they are all like the new one. The only one that I found that looks like my old one was for a T-5 transmission and different flywheel.

So, mystery solved. The reason my clutch springs rubbed on my flywheel bolt heads was none of the reasons any of us guessed. It was simply the wrong clutch disc sent to me by Ft. Wayne clutch 2½ years ago, nothing more. Those much smaller springs on the correct disc will never come even close to my flywheel bolt heads. So, I don't need to do anything to them, not grind them nor replace them, and all will be well. And, if that rubbing was contributing to my clutch chatter, that may well be gone. If anyone has greater enlightenment than this please share.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end. *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 05-02-2017 at 12:18 AM. |

|

|

|

|

|

#117 |

|

Senior Member

Join Date: May 2010

Location: East Hartford, Ct

Posts: 5,898

|

It sure looks like the one with 6 smaller dia. springs is more likely to be correct.

The larger dia. springs as you say on the one with 5 is most likely the reason for the interference that was experienced and was incorrect to begin with.

__________________

DON'T RECALL DOING SOMETHING FOR MYSELF BASED ON SOMEONE ELSE'S LIKES OR DISLIKES |

|

|

|

|

|

#118 |

|

Senior Member

Join Date: May 2013

Location: Wellington, Kansas

Posts: 444

|

Glad you got it figured out Professor. Thanks for sharing the information.

|

|

|

|

|

|

#119 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

That one on the left looks more like the 9.5 inch Long type disc used on the 8BA ford cars but they didn't have the same spline. There were and still are aftermarket reproductions being made for these so folks have to keep an eye out for stuff like that. Just because it is made as a replacement doesn't necessarily make it a good fit. I would figure Ft Wayne would be aware of that but if not, someone should make them aware.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 11:12 AM.

Linear Mode

Linear Mode