|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Thanks to everyone's help, I have successfully removed the engine and transmission from my 1936 panel delivery with a 59AB engine.

It's going to be a long process, working full time during the week slows things down. I figured I would keep all of my engine related questions in this thread. The engine is stuck and this past weekend I realized that I would have a very hard time removing the pistons if I couldn't rotate the crankshaft. From looking at the engine I thought that it wasn't the pistons stuck but the valve lifters that were causing the problem because of how rusty they are. I took off the timing cover and removed the cam shaft gear and then I was able to rotate the crankshaft.   Now I am trying to remove the oil pump and it doesn't seem to want to come out. I removed the one bolt at the bottom of the oil pump (If engine is upside down)  Is there anything else I need to remove to get the whole pump out? |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Gardiner Me.

Posts: 4,200

|

Take a big pipe wrench and grab the big end of the pump, try to swist the pump back and forth. Don't worry about hurting the pump your going to replace it anyway. DON"T brake the pump off you'll be in deep s--t Walt

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

For stuck lifters I removed the pistons, crank and all valve assemblies. I soaked each lifter from both sides with the acetone/trans fluid (50/50 mix) for about a week. Some loosened, some didn't. I heated the rest with a propane torch then more 50/50. Few more still stuck. I got impatient and drove the rest out with a 1/4" brass drift next to the cam lobe. I did end up breaking two (Johnson style) lifters doing this. They seem hard, but they will shatter.

Lonnie |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

The first thing you want to do is get a good quality engine stand with an exhaust manifold adapter.. This will insure your and the engines safety. Now, you have to decide right now what you plan on doing to this engine and it's application and what you expect from it. THis is going to be expensive if you makes mistakes taking it apart. For instance, it has floating bearngs and they usually last for ever, but are very expensive. When you pull the rod caps make sure they go back on the rod the way they came off. Rempve the bearings and tape them together, they may be reusable. However if you plan on replacing all this they have value. Good luck, and Keep em runnin.

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: BIRTHPLACE OF SPEED, FLORIDA

Posts: 531

|

Get your self a STUMPY'S ENGINE STAND ADAPTER and save some later grief !

http://stumpysfabworks.weebly.com/st..._Products.html |

|

|

|

|

|

#6 |

|

Member

Join Date: Jan 2013

Location: Kansas City, MO

Posts: 41

|

Sponsored Links (Register now to hide all advertisements)

Last edited by kegmon; 09-03-2014 at 10:29 AM. Reason: clarification |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I had to make a engine stand adapter on my own. All the ones I saw wouldn't work with the engine stand I have, it is bolted to the exhaust ports and everything is grade 8 bolts.

The plan with this engine is to just rebuild it to get it running, no performance want to keep it simple and original as possible. I will be taking it to a machine shop to get it cleaned and checked for cracks. I guess my next step is to remove the flywheel and the back gear cover plate and the idler gear for the oil pump and then try to remove oil pump again. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Mac dozer

In this case the rods and bearings may be reusable. I save these for just such a rebuild and don't like using new bearings if I can find GOOD used ones. That goes for the 29A rods. Make sure the small ends are OK and only remove the bushings IF the shop has the proper tooling to replace them. Here again the wrist pin bearings rarely need replacing. These two items are the most expensive parts of an early rebuild. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Jun 2014

Location: Salt Lake City, Utah

Posts: 756

|

Quoting Ol' Ron,

"In this case the rods and bearings may be reusable. I save these for just such a rebuild and don't like using new bearings if I can find GOOD used ones." Ron, will you please elaborate on why you prefer good used bearings? I am new to flatheads and have a 1936 49B and another 59AB that I am tearing down to see which is in better shape for a rebuild. The 49B is apart and the rod bearings are inserts, they look a little odd from what I am used to in that they have what appears to be imbedded granular structures that do not appear to be from a foreign source, ie contamination. I have not yet checked the clearances pending a trip to the hot tank. |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

The 49/53 engines have lock in bearings, the same as most other engines. The pre 49 Ford engines all had floating bearings. This bearing does pt lock into the rod or anything else. It just floats between the rod and crank. These older bearings were mad from cadmium and silver in some cases. Heavy duty bearings were mad from a bronze alloy. These bearings MUST be fit to the crank. New replacement bearings are not of the same quality. Also NOS bearings have a tendency to flake from old age. so a good full flow oil filter is a plus for longevity. I cover this in my book.

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jul 2014

Location: Iowa

Posts: 1,634

|

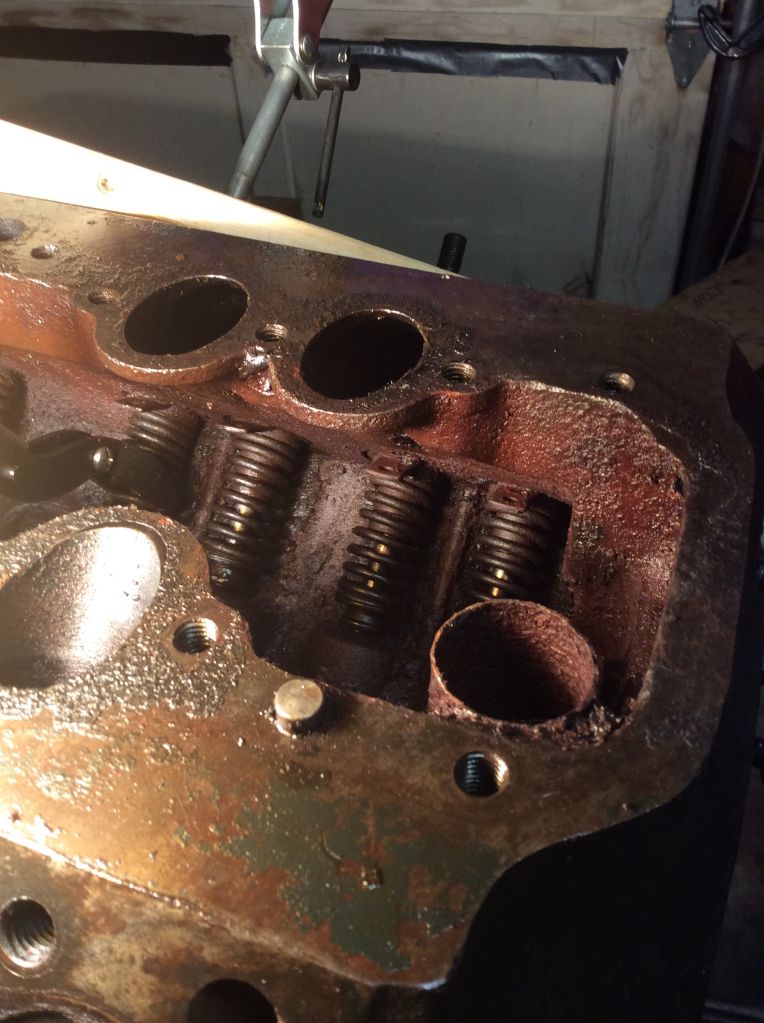

The photo shows orange gunk. That is almost always a sign that water entered the engine some time. The front shows evidence of the same. If it was stored in the open, it could happen. Otherwise, there may be cracks in the block that allowed water in the jackets to flow into the pan.. Look at the inside walls of the lower end for holes or cracks. that is the usual place for freeze cracks. We have seen too many like that to believe that block is worth rebuilding.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,524

|

There is no way to know whether the block is any good until it undergoes a thorough cleaning and inspection. Anything now is just speculation.

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

That engine looks like it has been through a storm flood.

Lonnie |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Have it baked cleaned. Mag first to save your money

|

|

|

|

|

|

#15 | |

|

Member

Join Date: Aug 2013

Location: Texas

Posts: 93

|

Quote:

. .

|

|

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Shelly at Mac VP is re doing it and it should be available soon.

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

How do you know that the bearings are good, what is the best way check them?

What if you find one bad bearing, can you replace just one and still use the other old ones? |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

What are the specs or where can I find what the allowable tolerance of the bearings and crankshaft are?

|

|

|

|

|

|

#19 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Most rebuild manuals have that type of information and I would bet Ol Ron's book would be one of them! Were you interested in specific suggestions on the manuals or just the sources in general?

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I have a few books, looking for all the info I can get. Believe it or not this engine came out of a panel delivery that was running 30 years ago and has been kept inside dry location ever sense, not sure what happened to it in that time.

What do most people do reuse old bearings or just put new ones in? I still have to measure and see what I have. From info I found on van pelt web site I should be looking for a measurement of no less then 0.1085 for the connecting rod bearings. |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: May 2010

Location: Charlotte NC KiWi-L100 available here

Posts: 2,953

|

I like to use fine scotchbrite on all my bearings .

Cheers Tony |

|

|

|

|

|

#22 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Not sure if the attached chart is helpful or not, see what you think. It is from the Ford Factory Refurbish Manual.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

Check out this site. Left column, half way down. Words from JWL himself...

http://www.btc-bci.com/~billben/flathead.htm Lonnie |

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Oct 2010

Location: North Pole, Alaska

Posts: 1,470

|

All good information. I'm planning on rebuilding a 38-41 motor soon, be nice if I could reuse a few things. It still has oil in it and turns over nice. I pulled a valve just to see how hard it would be and it came out easier than any old flathead I've ever messed with, kinda scared me! I plan to do only minimum needed and will probably pull sleeves as I have a new set of standard pistons for a 239.

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

When I started racing the Flathead back in the late 50's I had a good teacher when it came to fitting the bearings. There are probably several methods that work but the "Hammer" method seems to be the best. You might practice on an old bearing. Their are some tools that make everything work out better and one is a bearing mike or inside mike. this will accurately give the thickness of the bearing, which is important to getting the desired clearance. another important dimention is side clearance, not enough can cause hi oil pressure to damage the filit radius of the crank. This is called Cavitation erosion, and is prominent in cast iron crankshafts. too much can put too much oil on the cylinder walls. I use .020" for the bearings and .010" on the rods. The differance here is to relieve the pressure from the bearing before it gets to the crank radius. Non of this is all that necessary for a street engine, but when your turning 5+K all night long every week end, it works. Sorry to jump in here like this, but I don't need "H" beam rods, 21A and 29A rods work just fine.

|

|

|

|

|

|

#26 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Sponsored Links (Register now to hide all advertisements)

The one piston I removed the rod bearing doesn't look good but haven't measured it yet. If I do find that I have one or to bad bearings, or rods can I just replace the one rod and bearing and still use the rest of the bearings if they are in good condition? |

|

|

|

|

|

#27 |

|

Senior Member

Join Date: May 2010

Location: Charlotte NC KiWi-L100 available here

Posts: 2,953

|

Dont forget to get your KiWi-L100 cam....

Good luck !! Cheers Tony |

|

|

|

|

|

#28 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

|

|

|

|

|

|

#29 |

|

Senior Member

Join Date: May 2010

Location: Charlotte NC KiWi-L100 available here

Posts: 2,953

|

|

|

|

|

|

|

#30 |

|

Senior Member

Join Date: May 2010

Location: Larry Young, Tulsa, OK

Posts: 202

|

I am just now going through the decision about replacing rod bearings. The 0.1085 is for bearings in an original engine. If the crank pins have been ground or the rods resized, a different number will apply for the oversized bearings. I have looked through many books, but have never seen a number for the thickness of original bearings with no wear. When original the rods were 2.360 and crank 2.139, which give 0.004 clearance with 0.1085 bearings. I would like to know the correct clearance for new bearings

Larry Young |

|

|

|

|

|

#31 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Where would I be able to get bearings and a connecting rod? If needed

|

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: Larry Young, Tulsa, OK

Posts: 202

|

I have a question about rod bearing material. Why were the older bearings bronze or copper looking rather than the more conventional Babbitt. I think all the new bearing available or Babbitt. Which is better?

Larry Young |

|

|

|

|

|

#33 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

For floating bearings, you need the Bore diameter of the rod 2.220 for the 21A.

Bearing thickness times 2 for the bearing .108 x 2= .216 Crank throw 1.998 and add the crank to the bearings and you get 2.214 total clearance would be .006". Now when you mike the bearing thickness the .108 is very small .109/.110 is more likely. Then have the rods honed to 2.221" I realize this is for the 21a rods, but it 's the same math for the 29A rods. I like to run these bearings alittle loose. Watch out for thr cranl fillit radius, it may drag on the bearing. Once the bearing is fit to the rod and crank scuff with #400 paper, wash in soap and water, akk assy lube and make sure the oil pressure is 40/50 lbs hot. With a good symthetic oil thay should last forever. I'm not sayint this is the only way to do it, it's the way I did it and it works. But the flathead is very forgiving and I'm sure others have good ways to do it as well. Good luck. |

|

|

|

|

|

#34 |

|

Senior Member

Join Date: Jul 2014

Location: Iowa

Posts: 1,634

|

Given the evident condition of that engine, it is likely not much can be reused, including the bearings. Have both the rods and crank carefully measured by a good shop to determine both the size and condition. We have encountered cranks with odd sizes on the same crank, probably due to regrinding at some time. When you order bearing sets, check each pair to be sure they match the size on the box. For some reason, we have recently received cartons with mismatched sets. Camshaft bearings are another critical place, as bad bearings will affect oil pressure.

|

|

|

|

|

|

#35 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Great info thanks for the responses. Does anyone know of any good shops with flathead experience in NH or VT?

|

|

|

|

|

|

#36 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Can anyone recommend a good style slide hammer to use when removing the oil pump idle gear?

|

|

|

|

|

|

#37 |

|

Junior Member

Join Date: Mar 2011

Location: Santa Cruz, Ca

Posts: 4

|

I've had crank rod journal wear problems with Johson bronze floating bearings on a offset ground 4 in merc crank

|

|

|

|

|

|

#38 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

For those using the 21A rods, I cut the flanges off the early 32-37 bearings. Some of these are cad.silver and run forever properly set up

|

|

|

|

|

|

#39 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Should this oil pan be flattened out at all or will it be fine to use it the way it is?

And what is the purpose of this what the arrow is pointing to?

|

|

|

|

|

|

#40 |

|

Senior Member

Join Date: May 2010

Location: Charlotte NC KiWi-L100 available here

Posts: 2,953

|

|

|

|

|

|

|

#41 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,742

|

Hard to say whether the pan should be straightened, if you think you can improve it, give it a go. Don't go mad, a couple of well placed blows should get it straight enough.

The triangular piece is the road draft breather vent. Ford very cleverly incorporated it into the engine rather than as a bolt on. The vent aligns with a passage that has a tube fitted at the top, the open end of which is tucked right up under the inlet manifold. Mart. |

|

|

|

|

|

#42 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Walt Dupont is just an hour or so into Maine

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Thank you for the info..

I am still in the process of disasemble. I have honed the clylinder walls very lightly and no ridge at top to speak of but the pistons seem to get hung up on the last ring, it will come out most of the way but the last half inch goes harder .I have got four out buy spraying with pb plaster and slowly working it out. Is this normal? Also a few of the rod bearing caps don't seem to want to go back on after removal am I doing something wrong?

|

|

|

|

|

|

#44 |

|

Senior Member

Join Date: Oct 2010

Location: North Pole, Alaska

Posts: 1,470

|

They will go on, just pull them off and keep trying, have to be aligned straight to go on, sometimes you can rock them slightly from one stud to the other and they will go on.

|

|

|

|

|

|

#45 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Update I have removed all the pistons and oil pump. To remove the oil pump I had to remove the oil pump idle gear off of the cam shaft gear. The valve lifters are all stuck.

So now I am trying to remove the valves. Again I am working on a 59ab. I thought I would have the valves for 48 to 53 as seen here http://www.vanpeltsales.com/FH_web/f...al_tools-1.htm But don't see how to remove the valve sleeve or the locks, I don't see the locks at all. Here is what I am looking at.

|

|

|

|

|

|

#46 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#47 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Looked at the last photo again, you are moving the spring in the wrong direction!! It comes down from the top and the retainer with the tab with the hole in it has to be pulled out. I can't tell from the photos which valves you have, but the only real difference is straight on the stems vs tulip shaped and split vs solid guides. I would guess late model valves (straight with solid guides) but it's only a guess.

Edit: VanPelt says you can remove the retainer from the valve stem and take the valves out through the top, I have never done it that way. I now see that is what you were attempting to do. Looking again, you may have the tulip valves. VanPelt has a procedure for that spelled out also. In last photo did you attempts to pry the part up with a screwdriver that is sticking out below the retainer? It is either the sleeve that the keepers are in or the tulip end of a valve. Should be able to figure that much out fairly easily. If it is the sleeve the keepers should fall out if you pry it up (look at the figure for 51-53 valves). Last edited by JSeery; 10-18-2014 at 06:29 PM. |

|

|

|

|

|

#48 |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,524

|

Pulling the valve spring down will not release the guide lock. You need some special tools for doing the job. By the looks of the valve keepers, you have the mushroom stem valves. Makes things harder. There is a notch in the valve guide near the end of the small diameter that is meant to be engaged with a special tool. This is used to pull the guide down allowing the removal of the guide keeper. Then the assembly is pryed upward and out. There is also a tool that can be inserted in the hole in the guide retainer that can be used to pry the retainer out. Probably the easiest method.

Last edited by flatjack9; 10-18-2014 at 07:11 PM. |

|

|

|

|

|

#49 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

Those are late 8BA rotator retainers and springs. How they get removed depends on if you plan on reusing the valves.

This is the crudest but quickest way if you don't plan to reuse the valves. https://www.youtube.com/watch?v=z8iGXa9H294 Lonnie |

|

|

|

|

|

#50 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I don't see how I could have the mushroom style valves the valve spring retainer and the sleeve both rotate/ spin freely around the valve. The valve does not rotate. It seems like the locks might not be coming out or down.

|

|

|

|

|

|

#51 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Need to tap/bang the sleeve around to get the locks to come out. Looks like you have the late model valve setup for sure if that is a sleeve.

|

|

|

|

|

|

#52 | |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,524

|

Quote:

|

|

|

|

|

|

|

#53 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,742

|

I believe you do have the late rotator valves fitted. This is a definite plus when it comes to dis-assembly. The conventional way of pulling the guides down, pulling out the horseshoe clip and then withdrawing the whole assembly as a unit is probably best bypassed in this case because the guides look like they will not move easily enough for that to happen.

Get your valve tool behind the small retainer at the end of the valve, lift it (you might need to tap the valve head gently to break the taper) and the collets should come out. Then withdraw the valve, tap the guide down a little way(using a long socket or similar), remove the horseshoe clip and pull the spring and guide up and out of the block. Piece of cake. Mart. |

|

|

|

|

|

#54 |

|

Senior Member

Join Date: May 2010

Location: Cincinnati, OH

Posts: 1,361

|

Definitely the 51-53 rotator type valves. This link shows the three types:

http://www.vanpeltsales.com/FH_web/f...al_tools-1.htm We rent a removal kit for flathead valves but I think you can get these out with a good quality valve spring compressor. This link shows the kit: http://www.vanpeltsales.com/FH_web/F...-rentalkit.jpg

__________________

VANPELT SALES LLC Cincinnati, Ohio Office: 513-724-9486 www.vanpeltsales.com www.classictransmission.com |

|

|

|

|

|

#55 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Thanks for the help. All good things to know.

The reason I think I have the later valves is that the spring retainers don't have a notch in them. They are perfectly round. The sleeves don't seem to be moving up or turn on the valve stem like I first thought they were. |

|

|

|

|

|

#56 |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Hi Mac, it would be much easier getting the locks out if you had "straight" fingers on the spring compressor!

Without the correct fingers it's difficult getting the angle with the tool to grab the springs up high! Thanks, Gary in N.Y. P.S. Here's a shot of the springs being compressed, actually takes only about 5 or 10 minutes or so to get all the locks out. Of course the air-operated compressor makes it a little easier also!

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

#57 |

|

Senior Member

Join Date: Feb 2011

Posts: 253

|

Absolutely forget what you see in the manuals; it ain't coming apart that way. You have years of carbon and sludge locking the whole assembly together, not to mention water damage. For that condition engine no special tools are required. A piece of rebar or round stock heated on the end and flattened out with a groove ground in it, a hammer, a screwdriver, and a socket/punch slightly smaller than the valve guide bore is all that is required. Pry the valve spring up and hold it there, hit the head of the (raised) valve with a hammer, this will knock off the locks. Sometimes one will stick, repeat or use screwdriver to tease it off. Remove valve spring prying device. Place crowbar under head of valve and pry it out of the guide. get spring and retainer out of the way. using suitable socket/punch drive valve guide down the bore into valley. Once you do one or two you will get the hang of it. Start with easy to access ones; save difficult ones for last.

|

|

|

|

|

|

#58 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,057

|

Once I've made the decision to replace the valves, guides, etc. (which is an easy decision to make), then some level of 'violence' usually comes into play.

This is especially true with older flatheads with mushroom stems and split guides - nothing for me to ponder saving. With later one-piece guides and 11/32 stem valves, sometimes you can save them, but if they are frozen, rusted, obstinate, etc - get them out any way you can. I've used cut-off wheels and air tools to cut springs/stems. I've raised valves and knocked their heads off with hammers, heck - I even used a big ole' set of bolt cutters to cut the valves stems - whatever gets the job done. Once you know you're not hung up on saving the old stuff - you can get a lot more brave.  Having a large/long forged valve bar is REALLY important - as I can use it to lift the springs up, let the keepers fall out, etc.. I have never used one of the big C-Clamp style of tools - just a real pain getting them into the valley in all the weird angles. I'm sure that if I liked that approach, I'd just modify one to work a bit better - but don't see much of a need. Anyway, best of luck - take all the ideas you've been given . . . see which ones work for you and get after it. In a few hours of time you'll have it all taken apart. B&S |

|

|

|

|

|

#59 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

The best and easiest way to remove valves, is: Have somebody else do it. I've been taking a block apart for over 2 years now, it's been a long and bloody fight and their's only a few valves left.

|

|

|

|

|

|

#60 |

|

Senior Member

Join Date: May 2010

Location: Larry Young, Tulsa, OK

Posts: 202

|

I am also in the middle of a rebuild of an A block (38-41) with a 59AB crank. I was able to get the rear rope seal retainers from Vanpelt. I want to use a crab distributor with the original cam. I know it will need a 3 to 2 bolt adapter. Is this all I need to work with an early cam with the longer nose?

Larry Young |

|

|

|

|

|

#61 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,742

|

^^

Yes. The thickness of the adaptor compensates for the length of the cam. |

|

|

|

|

|

#62 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I finally got one of the valves out.

Thanks to everyone's help. The camshaft does not rotate I think some of the lifters Are stuck. How can I go about removing the valves that are in the Open position? |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#63 |

|

Senior Member

Join Date: Oct 2010

Location: North Pole, Alaska

Posts: 1,470

|

Try this, if the valve is open, turn engine on stand with valve pocket facing up, pour a small(capful) amount of your favorite flammamable product, I used denatured alcohol, then light it. Let it burn completely out then go in with your valve fork and try to move the guide. The direction you move it will depend on wether the "C" clip is still holding guide.

I'm tearing apart a 1940 block now and all the exhaust guides are stuck. P.S. Do this in an open area, and keep a fire ext handy. |

|

|

|

|

|

#64 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Unless you are wanting to save the valve and springs for some reason the best method is to cut them. You will be forever trying to take it apart otherwise. A cut-off wheel works as do other instruments of destruction. That's just the nature of the beast with an engine that is completely curded up and even at that it is a major job getting the guides out. You will be far better off replacing the valves and spring and guides on an engine in this condition.

|

|

|

|

|

|

#65 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

|

|

|

|

|

|

#66 |

|

Senior Member

Join Date: May 2010

Location: Larry Young, Tulsa, OK

Posts: 202

|

Sponsored Links (Register now to hide all advertisements)

Larry Young |

|

|

|

|

|

#67 | |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Quote:

|

|

|

|

|

|

|

#68 |

|

Senior Member

Join Date: May 2010

Location: Larry Young, Tulsa, OK

Posts: 202

|

We talked about full floating bearings above and that was the main reason for my post. I was surprised they fit so easily. Or, am I missing something?

|

|

|

|

|

|

#69 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Nope, just thought you might get more noticed on a new thread, if you like it here great.

|

|

|

|

|

|

#70 |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Hi Larry, just an important tip to others here doing any assembling on ANY build, doesn't matter the mfr, the very first item to check is to make certain the cam fits the newly installed cam brgs, this is done first!!

When we do the cam brgs here we always try a cam for fit BEFORE the job is delivered and the customer finds the issue. We have almost all brands (mfr's) of cams to work with, we tape up ALL the lobes and any gears and try it for fit! There is nothing worse than a customer calling and saying "I can't get the cam in OR I can't turn it when it goes in", this is very frustrating to the assembler. And this is why I say this should be the very first checkpoint. Too many assemblers go ahead and install the crank, rods, and pistons first and then "hit" the panic button when it's the cams turn! Having it all together makes a "cam-brg-repair" that much more difficult. Thanks, Gary in N.Y. P.S. I'm curious if you "honed" directly on the cam brgs OR the cam brg holes in the block?? You cannot "hone" babbited material, the grit WILL embed it self in there!

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

#71 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I was hoping to reuse these valves if I can.

The only way I have been able to get the keepers to drop out is to lift the valve up with the bar "pickle fork tool" and place a piece of wood on top of the valve and hit it down with a hammer. Hoping this method is ok. |

|

|

|

|

|

#72 |

|

Senior Member

Join Date: May 2010

Location: Larry Young, Tulsa, OK

Posts: 202

|

I know not to hone Babbitt, but did not know what else to do. I've bought bearings for two engines now and both sets of cam bearings were two small. Who makes bearings that fit?

|

|

|

|

|

|

#73 | |

|

Senior Member

Join Date: May 2010

Location: Kerrville, Tx

Posts: 2,768

|

Quote:

|

|

|

|

|

|

|

#74 | |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Quote:

We use only the Durabond line and we have them "Teflon" coated by Calico when the customer requires the coatings. We've been using this procedure since the coatings began. We like it due to the fact most cam-to-journal clearances on this platform are generally on the loose side, hence the coating! Thanks, Gary in N.Y. P.S. I would strongly recommend getting an accurate size on all 3 cam tunnel holes, this is a starting point! The holes should be 1.928" +/- .0005"! Also double check the cam journals, they should be between 1.796"/1.797".

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

|

#75 |

|

Senior Member

Join Date: May 2010

Location: Ft Mohave,Az

Posts: 1,985

|

Macdozer:

The only way I have been able to get the keepers to drop out is to lift the valve up with the bar "pickle fork tool" and place a piece of wood on top of the valve and hit it down with a hammer. Hoping this method is ok. Becareful with the hammer valves are easily bent. Use the big C compresser. |

|

|

|

|

|

#76 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I have been using the Valve spring compressor and think I have gotten the hang of getting these valves out. Only four more to go. Thanks for all the help.

|

|

|

|

|

|

#77 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I have gotten the block all disassembled and now ready to take it to the machine shop. Going to take the block to L &R machine in clarmont, nh who have done a bunch of the flatheads.

Just going to have it mega fluxed first hopefully everything is ok. Is there any recommendations or advice that might be usefull to know. |

|

|

|

|

|

#78 |

|

Senior Member

Join Date: Oct 2010

Location: Chattanooga, TN

Posts: 1,093

|

Good luck on your 59A build! I built mine last winter with the help of Ol'Ron's book and many members of the Barn. My 37 is my daily driver and so far no problems. you could probably search my threads and posts to help answer some of your questions. Good Luck!

|

|

|

|

|

|

#79 | |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Quote:

Ask the shop if they use a block-plate when finish honing the bores?? and see if they are able to pin the heads and gaskets to the block like the SBC's?? Thanks, Gary in N.Y. P.S. Also ask about modifying the block for the 95% oil filtering setup. This is the time to have that done.

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

|

#80 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

What does the block plate do when finish honing the blocks?

And what does pin the heads and gaskets to the block mean? How necessary is the 95% oil filtering setup? |

|

|

|

|

|

#81 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Just wondering because this the first flathead I am rebuilding.

|

|

|

|

|

|

#82 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,742

|

Dozer, the 3 things mentioned are sort of optional extras done by top notch shops. The hone plate holds the block in the same condition that it would be with the heads torqued down, so that when it gets honed the bores will be as true as possible when the head gets fitted. Pinning the heads to the block means using a dowel type setup. to ensure the heads are always located in the same position. The 95% oil setup is a good thing to do, but again the vast majority of these old motors run with the factory bypass oil system and tons more run with the original factory setup of no oil filter at all.

It pays to be aware that these options are available but they are by no means essential for a run of the mill flathead rebuild. Just my opinion, not trying to rubbish anyone's suggestions. A newb can become confused if barraged with advice when some of that advice is not essential. Keep doing what you are doing to get the valves out, be gentle, you might bend some. If you look underneath, you can see which lifters are stuck up. you should be able to tap these back down. That said, a lifter/valve stuck open should not stop the cam from turning. You need to locate any that are stuck in the closed/down position. Mart. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#83 | |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Quote:

When you assemble the unit and bolt the heads on the bores will still be round. I doubt Ford ever did it this way, but today it is the "norm". Pinning the block/heads/gaskets keeps everything from "moving" around. With the use of any aftermarket aluminum heads lately it's good precedure. The mfr's have made the head bolt holes much larger than in the past. The block-plate serves as 2 tools for us, first for the "pinning" and second for the honing. It is used for both procedures. Thanks, Gary in N.Y. P.S. The oil filtering mod is just a real good feature, and now is the time to do it, during a complete teardown. Even if you decide against using the filter setup it's nice to have it there if you change your mind! Here's a shot of the plate, the pinning setup, and the filter mod.

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ Last edited by GOSFAST; 11-23-2014 at 04:57 PM. |

|

|

|

|

|

|

#84 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Update. I brought the block to the machine shop and checked for cracks.

NO Cracks, good news. The bad news is that some of the cylinder walls do have some bad pitting and the shop is recommending boring it 0.030 over. He said he will try honing first. I was really hoping that I would not have to bore it out, is there any advice anyone can give me. If I do get it bored to 0.030 over what are my options with new pistons, where can I get new ones from? |

|

|

|

|

|

#85 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

99.9% of the flathead rebuilds never see a torque plate, including the originals. It's just a good idea, I think??

|

|

|

|

|

|

#86 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

Sponsored Links (Register now to hide all advertisements)

Lonnie |

|

|

|

|

|

#87 | |

|

Senior Member

Join Date: May 2010

Location: Victoria BC Canada

Posts: 354

|

Quote:

|

|

|

|

|

|

|

#88 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Update and question , the block has checked out ok but will need to be bored. The crankshaft also needs to be turned which wasn't a surprise to me it has some bad pitting on the journals.

I am wondering what to order for valve lifters? Should I get adjustable lifters? Where is the best place to buy the valve parts from, guilds, lifters, ect... |

|

|

|

|

|

#89 | |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Quote:

We use only the original "Johnson" tappets, SBI stainless valves, and most times Ross pistons. The Ross piston/moly-ring pkge allows for some extra HP. We do use the OEM style 4-ring pistons on occasion but rarely. You may want to consider a stroker kit, not sure about your budget?? (Add) "Happy New Year" to all here! Thanks, Gary in N.Y. P.S. The guides get lined, machined for seals, and we use the new "Viton" valve stem seals. This is all part of a pkge including 16 new guide locks (the horseshoe guide retainers), new seals, and a new set valve locks.

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ Last edited by GOSFAST; 12-31-2014 at 08:42 AM. Reason: Add info |

|

|

|

|

|

|

#90 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Gary I think the guy is trying to save money on a stock rebuild. What you suggest is alittle overkill. 49-53 stock guides and valves. Knurel guides for tight fit and he's golden. #40 of stock spring pressure on a stock cam and you can use any adjustable lifter. Clearancing them the old fashon way is very expensive, IF you can find anyone to do it. Walt is along way off. We have to come up with some reasonable rebuilds so more people do it and don't start installing those belly button engines.

|

|

|

|

|

|

#91 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Yes this is a stock rebuild. I was thinkinking of getting new valve guilds but would the old ones be ok to use if I can reuse the valves?

As for the adjustable lifters I see there are a few different types and was wondering what ones would be good for a stock rebuild. |

|

|

|

|

|

#92 | |

|

Senior Member

Join Date: May 2010

Location: Florence Ma.

Posts: 2,404

|

Quote:

Only 1st cup of tea so far, Brain ain't awake yet. What is belly button engine ?? THANKS |

|

|

|

|

|

|

#93 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Bill, that's funny???

|

|

|

|

|

|

#94 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I see reds headers sells Johnson style adjustable lifters, solid and hollow wondering why the difference?

|

|

|

|

|

|

#95 | |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,106

|

Quote:

|

|

|

|

|

|

|

#96 |

|

Senior Member

Join Date: May 2010

Posts: 886

|

Go fast, what are the part numbers for the valve seals ? or better yet what engine are they actally for , I have some left overs from sets of overhaul gasket kits , I dont want to starve my valves for oil by using the wrong ones,are the phospher bronze bushings from goodson a good way to go? how thick is your torque plate?

anyone know if a boring bar stand off plate for boring blocks without removing head studs will work in place of a torque plate? Thank for you many contributions in the past ,I really learn a lot from all here! Fordestes, |

|

|

|

|

|

#97 |

|

Member

Join Date: Nov 2014

Location: Coast of Maine

Posts: 44

|

This is all very interesting and helpful to many of us sitting on the side, as I too will

need to learn a great many small bits of vital information and looking to you folks. Please pour all your knowledge and insights into this thread, as many will benefit. Book recommendations, return links to past threads, insightful personal anecdotes... Cheers ! |

|

|

|

|

|

#98 |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

1. Go fast, what are the part numbers for the valve seals ?

Ans. We order the seals from the mfr (Global), either 100 or 500 at a clip, depending on our inventory level at the time we order, our part number in the computer is VS-1025, not sure about the original mfr number? I don't have that available. 2. or better yet what engine are they actally for, Ans. Not sure?? We buy them by size & material, .343" x .500" x Viton. There are other sizes but this fits the Flathead guides nicely. 3. are the phospher bronze bushings from goodson a good way to go? Ans. The K-line or Goodson liners are the brand we use, #KL-1958 I believe is correct number. 4. how thick is your torque plate? Ans. The plate measures 1.500" and has been made in house to handle a few different operations, the 2 main ones being the final honing and locating the dowel pins. 5. anyone know if a boring bar stand off plate for boring blocks without removing head studs will work in place of a torque plate? Ans. Would most likely be a bad idea, not much boring from the deck surfaces is being done anymore, most are done from the mains. 6. Thank for you many contributions in the past , I really learn a lot from all here! Ans. Thanks, you're very welcome. Thanks, Gary in N.Y. P.S. We make much of our own tooling, dedicated to each procedure. We have a very specific setup to install & size the bronze liners in the Flathead guides. With the block plate setup as it was built we are able to dowel-pin a block here today and install pre-pinned heads (maybe done at a much later time) for a perfect fit. It makes every pinning operation "standardized".

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

#99 |

|

Senior Member

Join Date: May 2010

Location: Florence Ma.

Posts: 2,404

|

|

|

|

|

|

|

#100 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

If I go with Johnson style adjustable lifters do I have to drill a hole in the lifter bores in the valley ? Or can adjustment be make without drilling the hole?

|

|

|

|

|

|

#101 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

I think the biggest problem here is the definition of a rebuilt engine. When rebuilding an engine you can make some modifications that will improve reliability, power and economy. With out spending any more money than a stock rebuild.

Unfortunately, a "Souped up engine" lands in a different class and depending on your pocket book can be quit expensive. But after spending all that money the power output will still be less than a hot rice burner. "Aesthetics" cost money, even on the inside of the engine, Like. Aperson asks "can I use solid adjustable lifters?" Why not? they work just as well as the lighr weight ones, in a stock or mild rebuilt. Garry want's to use Bronze guides. Nice do they work" Yes. are they the best you cna use in you engine? Yes. But knurelled stock guides work very well too at less than half the cost. Then we go to pistons. Forged or cast. Racing, I'd use forged. for street I'd use cast. Balancing, again, it depends on the rotating assy if you have all the original stock parts and only change pistons, not necessary. The vast majority of rebuilt engines never get re- balanced. This could go on, but I just want youse guys to think about tje application of your engine before you plunk down the$$$$$$. The hourly rat of these shops have gone up to the point that if we don't come up with a reasonable rebuilt engine the Flatheat head will go the way of the Gooney bird. |

|

|

|

|

|

#102 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Totally agree Ron

I'm just trying to do a stock rebuild for this one. From what I am finding out it looks like to use adjustable lifters a lot of people drill the holes in the lifter bores to ease valve adjustment. As of now I am thinking of getting the lifters from reds headers http://reds-headers.net/index.php?ma...&products_id=4 I am wondering about cleaning up the valves I have a sand blasting cabinet and have some new glass media that is 40-80 grit material does any one know if this size grit will be ok? |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#103 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Yes, by all means, drill the adjustment holes. Buy a 3/16 long drill at a hardwarre store to make the job easier. Drill the hole just above the oil tube. Make sure you knock the bore off the inside of the lifter boe. I use a wheel cyl hone. Also for those using a hi lift cam, grind of about an 1/8" off the top of the lifter bore, so the wrench will fit..

All this does is to make sure you do more than one flathead |

|

|

|

|

|

#104 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

What is the reason/ theory with the different styles of adjustable valve lifters. Why the adjustable hollow lifters and the solid adjustable?

|

|

|

|

|

|

#105 |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,524

|

The solids are generally cheaper.

|

|

|

|

|

|

#106 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#107 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Thank you that clears things up for me.

I haven't cleaned up the valves yet and wondering what some of you do to clean yours? But also wanted to know if I can't reuse the valve seats and have to install new ones can I reuse the old valves? |

|

|

|

|

|

#108 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

What I do to clean valves that might be reusable is scrape them as clean as possible with a safety razor blade then spray with oven cleaner, let sit for a day and scrub with a wire brush. Repeat. Oven cleaner works on seats too. A few years ago I used carbon tetrachloride but The EPA decided I was a threat to myself and all creatures on earth.

Lonnie |

|

|

|

|

|

#109 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

If the seats are good why change them? same with the valves. Make sure they are not to thin after they have been refaced. Take the sharp edges off then and the seats after they're finished.

|

|

|

|

|

|

#110 |

|

Senior Member

Join Date: Oct 2010

Location: North Pole, Alaska

Posts: 1,470

|

I've always just cleaned up valves on a wire wheel. Takes a little time, but it works well and is cheap.

|

|

|

|

|

|

#111 |

|

Senior Member

Join Date: Oct 2014

Location: Elgin, IL

Posts: 115

|

|

|

|

|

|

|

#112 |

|

Senior Member

Join Date: Dec 2013

Location: Minnesota, Florida Keys

Posts: 10,299

|

Does anyone have a source for knurled guides, or is it something any reasonably equipped local machine shop can do? (I'm building stock or close to it.)

|

|

|

|

|

|

#113 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

Tubman, start a new thread asking about guide knurling so Macdozer's thread doesn't go off-track. I have an idea on the subject.

Lonnie |

|

|

|

|

|

#114 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

While I was pricing out parts it seemed like Reds headers had decent prices.

With every thing, adjustable lifters,valve guides, springs and other hard ware it was about $350. But I see reds also sells some valve changeover kits that includes new valves. For around 260 or $285 with the Lincoln springs. http://reds-headers.net/index.php?ma...roducts_id=307 http://reds-headers.net/index.php?ma...roducts_id=310 I'm Curious what some thoughts on going this route might be and if anyone here has used these kits before. |

|

|

|

|

|

#115 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Reds are what I used.

|

|

|

|

|

|

#116 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

It seems like the kit might be the way to go, even though I would like to use the old valves I'm trying to do what is cost effective and will also be reliable for many thousands of miles.

What is the difference between the stock valve springs and the Lincoln Zephyr valve springs ? |

|

|

|

|

|

#117 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,057

|

The decision to use or not use old bearings comes down to the condition of the bearings, the condition of the journals on the crank and the associated clearances.

If you're very familiar with looking at bearings, using micrometers and such - then you can check things out and make some decisions. Make sure you keep all bearings in order - so you know exactly where they came from. What I've found that in many cases the bearings had some 'crap' go through them - maybe even during the disassembly process (rust, etc) - and they get score marks in them as a result (especially the mains). I always replace them - but that is just me and the bearings in my case are a small part of my overall expense. If you're trying to be conservative on price, no reason you can't check them all out (along with the crank/rods) and see if they can be reused. Take some good quality close-up photos of the bearings and journals - I'm sure there will be many opinions on here to help you make your decisions!  Good luck, B&S |

|

|

|

|

|

#118 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,057

|

Valves: As I noticed you already had the late valves (non-mushroom stems), you may be able to reuse them. Clean them all up with a wire brush to get all the carbon/crap off them.

I would then put them in a lathe and check for straightness, then mic the stems and see what condition they are in and also see that they haven't been reground too many times - having no margin left for a regrind. If the valves look good, then I would polish the stems in the lathe while I was at it. I use some super-fine sandpaper that has already been used on something else - like 600 wet or dry. Springs: I'd probably pickup a set of springs no mater what - as your engine sat for a long time, had water in it (rust), etc.. The Zephyr springs just have a bit more strength (pressure on the seats) than stock springs. Typically they have about 55 lbs on the seat (at installed height). Guides: If your guides are good, you can reuse them - might be a good idea to send them to GOSFAST and have him put the bronze liners and seals on them - not a bad idea. |

|

|

|

|

|

#119 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Thanks bored&stroked

I will have to buy new valve guilds a few of them broke on the way out. After getting the engine cleaned up it has been bored out before . The Pistons also prove this they have 0.040 stamped on them. Looks I will have to go to .060 over. What is the best way to clean up the cylinder heads inside and out? |

|

|

|

|

|

#120 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I was wondering what method of cleaning the cylinder heads is. For now they are just sitting in some kerosene. Was thinking of getting them baked and then sand blasting them. I want to make sure the water passages are good and clean.

What are some of the best ways to do this? |

|

|

|

|

|

#121 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I have been looking for a engine gasket kit for the 59 ab and was wondering if anyone had any recommendations. Speedway, victor reinz , fel-pro, just wondering if some are better then others. Now that it is going to be 0.060 over bore will that affect what size head gasket I use?

|

|

|

|

|

|

#122 |

|

Senior Member

Join Date: May 2010

Location: Gardiner Me.

Posts: 4,200

|

The .060 only need the std. head gasket, I recommend the BEST brand gaskets set. They have every gasket you'll ever need in the set and the best rear main seal. Job Lot carry that and a lot of other venders. Walt

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#123 |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Most standard bore gaskets are 3.270", on a .060" over (3.250") the risk of having the "fire-ring" too close to edges of the bores is much too high. There's a real possibilty a portion of the ring will hang over the edge at 3.270". You may be "splitting-hairs" so to speak.

I would go for the 3.420" and have a decent safety-margin! Thanks, Gary in N.Y. P.S. We try to stay with the Fel-Pro line, never had a single issue so far. We do use the 1-pc front seal on all builds with the respective sleeve!

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

#124 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I see they sell composite and copper head gaskets in the kits which one is better ?

I am thinking of going with the standard head gasket size with the block being bored 0.060 over, not sure I understand GosFast comment on the fire ring being to close to the bore with these gaskets please explain. |

|

|

|

|

|

#125 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,057

|

What he's saying is that the steel/clad fire ring can get really close to the heat of the bore, which can cause it to prematurely fail (causing a blown head gasket). You'll probably have no problem with regular gaskets - but, if you go to the 'Big-Bore' gaskets, you'll have a bit more margin for safety and the issue goes away. Hope this helps.

|

|

|

|

|

|

#126 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Sponsored Links (Register now to hide all advertisements)

I have also been trying to figure out the clylinder head studs, when taking it apart the heads had Bolts, should they be changed to studs when I put it back together? Can someone tell me if these are the proper part numbers for the head studs for a 59ab with the original cast heads? 40-6065 40-6066 40-6067 And is there a good nut and washer kit advailable that is preferred? |

|

|

|

|

|

#127 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,057

|

The parts quality can vary - one of my friends ordered a stud/nut/washer kit and the nuts were so soft, I'm not sure they were even Grade 8. I prefer to use ARP stuff - it is by far the best and you know the quality is there. It may cost a bit more, but is the route I go.

I don't have my green book in front of me to lookup the part numbers, but here are two places that have a lot of quality parts: Vanpelt Sales: http://www.vanpeltsales.com/FH_web/e...prices-pg1.htm Reds Headers (These are all ARP studs, which is only what I use): http://reds-headers.net/index.php?ma...ort=20a&page=1 |

|

|

|

|

|

#128 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Many years ago I saw an ARP stud kit and the course thread length was too long. The stock stud seats into the block. The ARP are floaters. Whick could cause trouble in the blind holes at the end of the block. They may have changed them????? I use bolts.

|

|

|

|

|

|

#129 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Trying to figure out the oil pump for the engine (59ab) I think it is the long style and 50lb pressure. Is it best to get a rebuild kit for the pump ?

I want to make sure I get the right kit for the pump and any information would be great. |

|

|

|

|

|

#130 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

Macdozer, if you remove your pump's cover and see no unusual wear in the cover or gear mesh then put it back together. Ford long pumps are a notoriously good product.

Lonnie |

|

|

|

|

|

#131 | |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,057

|

Quote:

I'll check the thread lengths and report back. One has to make dang sure that the coarse threads are not too long and interfere with block internals - on ANY engine. This is an easy way to crack a block - ask me how I 'learned' this lesson! It is now something I always check.  I'll update this thread and make a new post later . . . probably next week. Dale |

|

|

|

|

|

|

#132 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

I'm also interested in this as I have a set as well.

|

|

|

|

|

|

#133 |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Let me clear up some specs on the ARP stud kits.

When the kits are ordered from ARP under a "standard" number they will package all the studs with 1.000" long coarse bottom threads unless noted. If you order the studs individual you can specify .750" long bottom threads! They make almost all their studs in both bottom lengths. The short's (.750") have a letter "S" at the stud part number end, the long's have an "L". The only holes that are really an issue are the 2 above the heatcrossover, occasionally they'll need to be shortened slightly regardless of the bottom lengths! Thanks, Gary in N.Y. P.S. On a side note, when we work with various brands of heads we find the machined heights are not always consistent. Also, on many heads there is add'l machining on the topside of the head bolt holes to make a nicer finished surface for the bolts or washers/nuts, we find this mostly on "used" aluminum castings.

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

#134 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,177

|

Quote:

|

|

|

|

|

|

|

#135 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,177

|

Quote:

|

|

|

|

|

|

|

#136 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

Ron Sangovinni (sp?) is a very good builder, especially when it comes to Ardun conversions. Excellent machinist.

|

|

|

|

|

|

#137 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Is the long style oil pump 50 lbs pressure?

I am looking to order some parts, like oil pressure relief spring and plunger. And also Oil pressure sending unit. Again 59ab engine. |

|

|

|

|

|

#138 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

|

|

|

|

|

|

#139 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

It's finally time to order some Pistons and rings and was looking for some advice on what to go with. The engine has been bored 0.060 over.

These are the pistons I am thinking of going with. http://www.speedwaymotors.com/1939-5...Over,1855.html And the rings. http://www.speedwaymotors.com/Flathe...ize,39162.html |

|

|

|

|

|

#140 |

|

Senior Member

Join Date: May 2010

Location: Napier, New Zealand

Posts: 2,001

|

Macdozer...... just my opinion, but a lot of Speedway stuff is chinese origin. I personally believe you are much better going for US made product. I know Speedway is convenient, but you will find much US product still around. Joblot is a very good source, and njparts who are an Ebay seller have a lot of NOS USA stock. Gaskets? Best brand is great, they have recently re-jigged their holes so that head gaskets just drop straight on.

|

|

|

|

|

|

#141 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Thanks for the info I will look into job lot , van pelt, for Pistons.

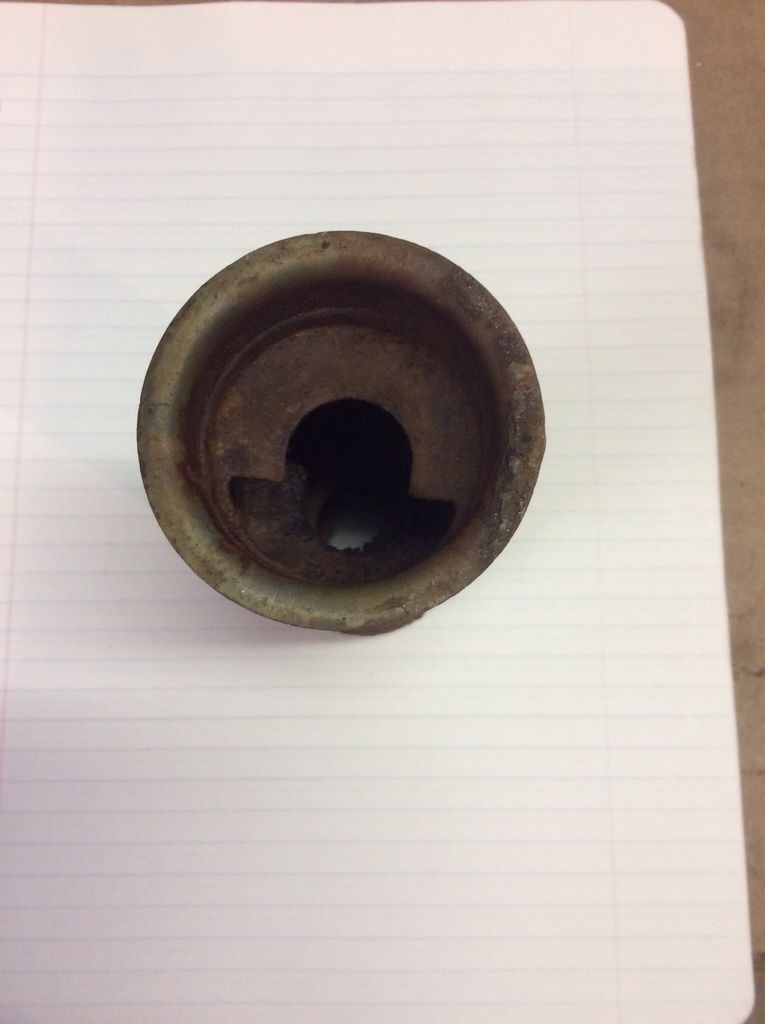

I am also looking for another part which I am not sure of the name of it. I believe it to be part of the 9415 assembly. It goes under the fuel pump and the fuel pump push rod runs inside of it. Here are a few pics.   Does anyone know where I can find one of these? |

|

|

|

|

|

#142 |

|

Senior Member

Join Date: Oct 2011

Location: Gloucester VA

Posts: 1,042

|

Drop it in some muratic acid/water solution to clean it up. Follow directions and DON'T DO IT INDOORS since the vapors are corrosive. It may come out useable.

Lonnie |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#143 |

|

Senior Member

Join Date: Jul 2013

Location: Sacramento, CA

Posts: 368

|

Or use a non-corrosive chelating rust remover such as: http://www.theruststore.com/Evapo-Ru...FcWUfgodORwAeg

I'd still like to know a source for the elusive "orange juice can", as I need one and suspect that they help avoid heat issues with the fuel pump. Anyone know a source? |

|

|

|

|

|

#144 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I not sure these one would clean up well enough to use. Does anyone have a source where I might find one?

|

|

|

|

|

|

#145 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Can someone tell me what the name of this part is?

|

|

|

|

|

|

#146 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#147 |

|

Senior Member

Join Date: May 2010

Location: Gardiner Me.

Posts: 4,200

|

There is 2 length of the depends on the height of the rear of the manifold. Walt

|

|

|

|

|

|

#148 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I've soaked it in vinegar for over a month and it cleaned it up well but I can see now that it has little holes all around it , does anyone have a source for these or does anyone have some good used ones available?

|

|

|

|

|

|

#149 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

For some reason, when disassembling early engines I seldom run across these tubes, And I've never used them, not sure just what they do, probably keep the firewall clean.

|

|

|

|

|

|

#150 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

It's just an oil baffle isn't Ron? Like you say, to help keep the oil in the engine and off the firewall.

|

|

|

|

|

|

#151 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,742

|

If there are just a few little holes, just weld em up. It's not a hyper critical piece. You ought to be able to find a barner willing to send you one, they should be fairly common, as all motors had them from the factory (ok, not the early ones).

|

|

|

|

|

|

#152 |

|

Senior Member

Join Date: May 2010

Location: Ft Mohave,Az

Posts: 1,985

|

Just J-B Weld them & smooth it up with the left over epoxy.

|

|

|

|

|

|

#153 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

I'm going to be using the oil pump that came out of the engine. I've been soaking it in kerosene for now. Trying to get this nut out but it is very tight. How much force should I use. .?

Sent from my iPad using Tapatalk |

|

|

|

|

|

#154 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Macdozer;1050837]Is the long style oil pump 50 lbs pressure? For this engine?

I am looking to order some parts, like oil pressure relief spring and plunger. And also Oil pressure sending unit. Again 59ab engine. Sent from my iPad using Tapatalk |

|

|

|

|

|

#155 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Are you asking a question or just providing an update?

|

|

|

|

|

|

#156 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Asking if the engine I have is 50 psi oil pressure or 80 psi how do you tell the difference?

Sent from my iPad using Tapatalk |

|

|

|

|

|

#157 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Can you use a 80 lbs oil pressure sending unit with a 50lb oil pump . Trying to figure out the right oil pressure for my engine 59 ab.

Sent from my iPad using Tapatalk |

|

|

|

|

|

#158 |

|

Senior Member

Join Date: May 2010

Location: Gardiner Me.

Posts: 4,200

|

That's a 50# pump, 46-48, it has straight cut teeth gears , not heilcol gears like the 80# 8BA engines, I use the 8BA pump in all my engines, it's shorter so have to use the 8BA truck oil pick up tube. Walt

|

|

|

|

|

|

#159 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

The oil sending unit doesnt care about the motor as long as instrument/sender match all is fine.

Oilpressure is more about what you need if you have raised the power you can raise the oilpressure if all stock you can leave it as is. |

|

|

|

|

|

#160 |

|

Senior Member

Join Date: Jun 2012

Location: Central NH

Posts: 192

|

Great to know thanks

Sent from my iPad using Tapatalk |

|