|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Sep 2011

Posts: 201

|

Hi all,

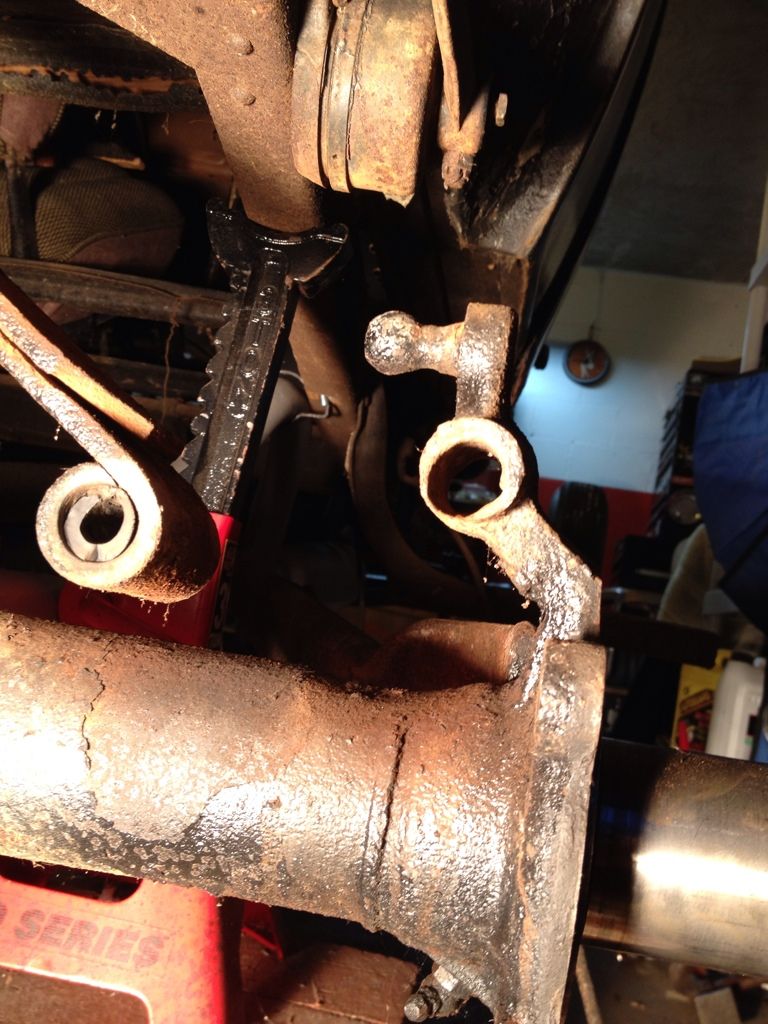

Let me start by saying i've been sparing no expense on my Model A, but my pockets have more lint then cabbage lately. Take a look at the pict below of my rear spring perches. The hole is oblonged, but the metal still runs the entire way across. My question, could I put the regular sleeve in and fill the worn area with JB Weld? In theory, this should work. Ok, let the a-hole ripping (or advise & suggestions) begin. As always, thanks Ford Bard brethren for your help!

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Oregon

Posts: 5,963

|

You notice what area is beat out. I think the JB Weld would be destroyed. Why not weld the area up with real metal and drill it out for the bushing which is steel by the way. If you want to just drive it just add the bushing with the split up. it will still support the spring shackles and maybe buy more time than you have. remember that ran for many years over washboard roads with scant lubrication to get that way.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Portland, Oregon

Posts: 5,906

|

My advice: Do it right. Weld it and drill it, as J Franklin suggests. It will be worth it in the long run. Or, as my dad used to say, "A year from now you won't miss the money and you'll have the job done right."

__________________

Ray Horton, Portland, OR As you go through life, keep your eye on the donut, not the hole.

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Southern California

Posts: 3,131

|

A shop here in Southern Califonia has a repair scheme. They insert a bronze rod the same diameter as a new bushing into the hole after the old bushing has been removed. They then weld the worn area and then pull the rod out. Apparently the weld does not stick to bronze.

Tom Endy |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

im just wondering how you could weld it up because you will only get metal into the shackle a quarter inch at best . drill it out completely and sleeve it with a new piece of steel ? but at the same time that looks damn thin on the bottom edge .

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#6 |

|

BANNED

Join Date: May 2012

Location: inside your RAM

Posts: 3,134

|

Sponsored Links (Register now to hide all advertisements)

__________________

'31 180A |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: So Cal

Posts: 8,754

|

I would go with Toms suggestion, I think you can also use carbon or copper rod.

Bob |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

also is this a cast piece? if so thats the next problem to weld with pre heating and post heating and cracking .

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: Santee, California

Posts: 3,505

|

On my car, when this had to be faced, I asked the JB Weld question also and was discouraged from doing same. I ran into the difficulty as well of welding inside that hole very far. I ended up putting a steel rod in the same OD as the replacement bushing, then heating the thin side to cherry red, and hammering or forging the remaining material up snug with the rod, I then only had to lay a few beads on top of what was the thin area to bring the thickness back to spec.

Flop, the material is a forging. |

|

|

|

|

|

#10 |

|

Senior Member

|

Russ, I like that!

__________________

What's right about America is that although we have a mess of problems, we have great capacity - intellect and resources - to do some thing about them. - Henry Ford II |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Apr 2011

Location: South pacific island

Posts: 1,724

|

Brazing the worn spot works well. Alot of filing to make it round for the bushing but better than nothing.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Parksville B.C. Canada

Posts: 880

|

That area is forged.

If you preheat the thin area with a torch, it is possible to fill just the valley with a mig welder by starting in the hot centre and welding out to the edge.....then go in the other end and fill it with weld from the centre out. -Preheating enables a mig welder to do extraordinary things Also...I can't see why a stick welder wouldn't work to fill the cavity if you had a steady hand... Forget about drilling the hole round, you'll mess up the entire good side doing so and likely break a few bits. I used a die grinder and finished with a rattail file till the bushing could be driven in place. I had to use a hand reamer in the bushing before the shackle would fit. |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Jul 2010

Location: Grand Rapids Mi

Posts: 168

|

I also did the same as Russ/40 and it worked great.

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: brentwood, ca

Posts: 4,246

|

my fix on several was to section a patch from 1 inch pipe(nongalvanized) and fit it to the damaged area aligning the patch. Then MIG welded in place. Bob

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: May 2010

Location: new britain,ct 06052

Posts: 9,390

|

Get a couple of diff axle housings??

Paul in CT |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Location: South East NJ

Posts: 3,398

|

Get a copper, bronze will work but the tin comes to the surface, the correct diameter. Does not have to be perfect. You might need to grind it some to open up the hole so you can weld along the length. Truth is if it is thin enough you will easily burn through and fill up the void. I have used brass and bronze in the past to back welds and did not like it, copper is best!!

If you are using a MIG welder also get some TIG rods of the same metal type to help the fill rate. Run the arc on the tig rod for a better fill. You do not need a perfect fill in, just enough to give support to the bushing you will put in place. Some voids and such are not a problem and you are likely to get them. The goal is to support the bushing properly. After you get the area nicely welded up drill to the proper diameter and make it look pretty. Press the bushing in place and you should be good to go. I had a really bad axle housing and did a practice try after reading about this a few years ago. Pretty easy to do and a great way to save a housing. |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2010

Location: Windy City

Posts: 2,919

|

It is possible to use an epoxy fill, but NOT JB Weld. JB is 'filled' with talc and limestone dust, resulting in excellent thixo, tensile, and bond properties, but low compressive and cyclic load performance. There are high compressive epoxies available, many with 20,000+ psi compressive strength. They use quartz or metal fill. Here's one with quartz fill, Supreme 45HTQ: LINK You can make your own by making a thick paste from fine iron filings and clear (unfilled) 1 hour or slower epoxy from a siamese tube dispenser. It helps if, before application, you can vacuum the final mix under a bell jar with an AC vac pump.

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Dec 2010

Location: FRESNO, CA

Posts: 12,560

|

Would it be feasable to replace that area with the spring eye cut from an old main leaf?? Bill W.

__________________

"THE ASSISTANT GURU OF STUFF" |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: May 2010

Location: Freehold, NJ

Posts: 113

|

I guess it depends on what might other problems with the rear exist. If it's in good operating condition sounds like the welding repairs are the way to go.

If it needs rebuilding either finding another axle tube may be the way to go. I too am in the same boat though I am starting with a chassis. The original rear is shot, axle keyways, spring perches and brakes toast. I picked up two other rears to make one. One had good brake assemblies and a hole in the axle tube the other rear was missing brakes and axles, tubes, and spring perch holes look good. In anycase good luck with the project and I would like to see how you make out. |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: May 2010

Location: Princeton, NJ

Posts: 965

|

I did the carbon rod weld thing on one of my rear axles, and it worked great.

Here are a bunch of photos: http://dougbraun.com/model_a_gallery3/suspension_work Doug

__________________

My '31 S/W sedan project:http://31ford.dougbraun.com My restoration diary: http://dougbraun.com/blog |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 02:35 AM.

Linear Mode

Linear Mode