|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#21 |

|

Senior Member

Join Date: May 2010

Location: Lynden, Wa

Posts: 3,552

|

Hi Brent and welcome.

When I took my engine out and put her back in we used two angle brackets that dad created out of 3/8" steel. We used two studs w/o the head and just positioned the chain and brackets so that everything was balanced front to back. Left to right is no real concern as there is nothing to hit and the engine minus manifolds is not side heavy. Mike

__________________

1930 TownSedan (Briggs) 1957 Country Sedan |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Location: Bozeman, Montana

Posts: 997

|

I have used devices like John Stone's angle iron and Tin Lizard's eye bolt to take engines out or put them back in. Both have worked fine except for the occassional alignment problems or rear engine mount problems. However, it seems like Mike K's device would work best to aleviate the above mentioned problems and for use on a vehicle that you shouldn't scratch.

I do love threads like this one....American ingenuity and multiple correct answers for the same question. Priceless. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 | |||

|

Junior Member

Join Date: Nov 2011

Location: Central FL

Posts: 15

|

Quote:

Quote:

Quote:

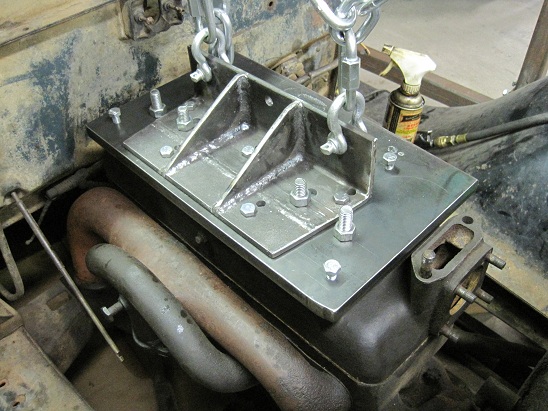

I got a little carried away with this project, but had a blast putting this stuff together. Here is the new lift bracket attached to the head puller. It has two sets of mounting holes so I have a couple options for side to side balance. I expect I will pick one position after a trial run and call it good enough.  The assembly seems like overkill (Ain't no kill like overkill). I think it will work fine with just the bracket, as seen below. Also pictured is the load leveler, completed over the weekend. Not pictured is a 1/2 ton hand lever hoist and small crane rig I use for various tasks.  The first lift will be a spare motor from a family member's pole barn in a couple weeks. Thanks to all for the helpful comments! |

|||

|

|

|

|

|

#24 |

|

Junior Member

Join Date: Apr 2011

Location: Pacific, MO.

Posts: 2

|

Reading this thread I had to make my first post. The damage to the end

spark plug threads was probably caused by lifting the engine using only a chain attached to the eyebolts screwed into the head causing a severe sideload on the threads. The use of a lifting plate (angle; plate etc.) which would put the threads under a straight line load a.k.a. tension. I am starting on the long process of putting a '31 Tudor back together that is a 31K mile car that was disassembled 10 years ago. Should be very interesting. |

|

|

|

|

|

#25 | |

|

Junior Member

Join Date: Nov 2011

Location: Central FL

Posts: 15

|

Quote:

|

|

|

|

|

|

|

#26 | |

|

Senior Member

Join Date: May 2010

Location: Jordan, MN

Posts: 1,411

|

Sponsored Links (Register now to hide all advertisements)

Quote:

Yes...you are right on..about 3/8" to 1/2" to the driver's side of the center studs. |

|

|

|

|

|

|

#27 |

|

Senior Member

Join Date: Aug 2010

Location: Auburn, Kentucky

Posts: 194

|

Hello Marc,

The engine lift and head puller comb pictured is my product. I have used it many times not only to lift the engines in and out but to pull a stuck head. I will tell you if you thread the lifting studs into the head with full engagment you will never damage or strip the threads unless some one previously damaged them. I have torqued the 7/16 diameter threads until the bolt snapped trying to remove a stuck head but the spark plug threads where fine. This lifter works great and was used to lift motors since high school when I was at home yet. I added the lifter to Ron Cloats stuck head puller Idea for a dual purpose tool. Hope this helps a little if anyone is thinking about purchasing one for the club or themselves. Thanks Bill Stipe www.stipemachine.com

__________________

Building Horse Power --

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 09:13 PM.

Linear Mode

Linear Mode