|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#61 |

|

Senior Member

|

I fitted a new clutch and PP( Imported ) after running it a while it developed some chatter ,I have Borg and beck setting jig so I set it up and found the fingers were not even ,I suspect the re popped clutches don't use hardened pins in the arms so something had worn .the clutch smoothed out on replacing it so having the finger s even is important ,just a few thou. In the light of that on a old ford clutch if the thrust bearing and it mechanism does not release the three fingers evenly then that may be a contributing factor, Ted

|

|

|

|

|

|

#62 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Fortunately, clutch chatter doesn't interfere with me driving my flathead over ten-thousand miles a year and most likely never will.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-04-2017 at 08:01 PM. |

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#63 |

|

Senior Member

Join Date: May 2010

Location: san antonio, texas

Posts: 461

|

|

|

|

|

|

|

#64 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Whew, mine isn't that bad. Whew, mine isn't that bad.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-04-2017 at 11:32 PM. |

|

|

|

|

|

|

#65 | |

|

Senior Member

Join Date: Nov 2010

Location: NM

Posts: 2,438

|

Quote:

__________________

'52 F-1, EAB flathead |

|

|

|

|

|

|

#66 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Sponsored Links (Register now to hide all advertisements)

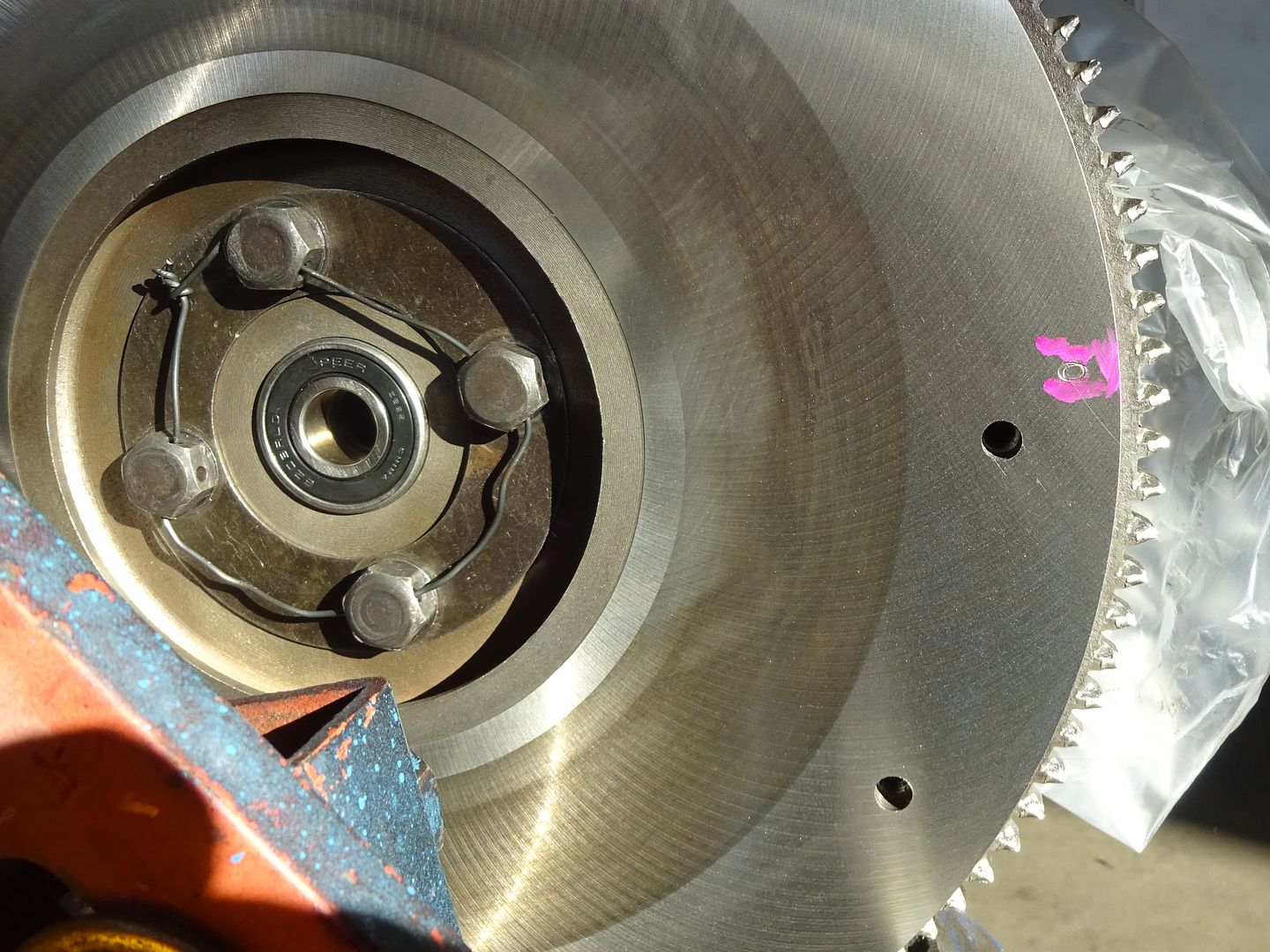

The flywheel was surfaced by the local racing machine shop, the same one that balanced every moving part in my engine that makes it run so smooth now. It doesn't look quite as bad in this light as the first picture on this post. It certainly was never as rough as the first picture looks and is smoother now than when first surfaced 38,000 miles ago. As far as I know, that was only the second time it had been surfaced. (The very slight wear shown is from the very brief driving of the car after the engine was first rebuilt but not balanced and had a bad vibration and had to be removed, dismantled, and balanced.)

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-04-2017 at 10:13 PM. |

|

|

|

|

|

#67 |

|

Senior Member

Join Date: Jan 2011

Location: sw minnesota

Posts: 4,574

|

long thread here! no one has pointed out the obvious here, the center plate holding the springs has wear too. certainly thats gonna have some effect, chatter-noise-somthing was going on near the end. 38000 miles, and always chatter? from day one? anti chatter rods tight to the frame? they are a bugger when the threads are bad or if you dont have the right size tool to tighten them. its a bastard size, not a 3/8 square, and bigger than a quarter. i made a tool on the mill and it lasted one bolt and was junk-too soft. next one i had to weld the head to the frame to get the nut off, then grind of the weld to get the bolt out. now, i order grade 8 allen heads from fastenal. so, are your bolts tight? next, flywheel surface. i have used flywheels that sat out side for decades and cleaned them up with 80 grit on a sander. never had a problem, unless it was obvious once the surface was clean. next is the issue of the disk center hitting the bolts. its from ft wayne, we'd all like to say its good, but if you still have another disk laying around, i'd like to know the distance from the hub to the spring cage that was hitting the flywheel. it could be a bad part. not ruled out yet. i'd take a grinder to the bolts if the distance is correct. next, clutch chatter can also come from other worn out parts. u joint would be obvious, you are there now, worn spline? bad front drive shaft bearing or thrust washer?, sheared pin on the rear coupler? also, as mentioned, it would be easy to check the runout of the flywheel, on the car. many crank grinders do not face that off unless you ask them to check it. i am not the expert here just maybe brought up some other points. i know you do lots of miles, bless you for that, i drive the heck out of my cars too. love your travel photos, and hows the new dog doing without a car to ride in? best wishes, skip

|

|

|

|

|

|

#68 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

No anti-chatter rods on a '47.

Dog has wife's RAV4 to ride in that she likes even better.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#69 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

The surface doesn´t look bad just so that it runs true, if it´s a machineshop building race engines they should know how to surface a flywheel.

I would look at the condition of the engine and gearbox mounts if they are soft or not tight you get shatter to. |

|

|

|

|

|

#70 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

|

|

|

|

|

|

#71 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,431

|

If the shop doing the flywheel doesn't have a rig like this then you have to be aware. Watch the video of the machine in action. You can see how bad a flywheel can get.

http://www.winonavannorman.com/produ...g5000_flywheel |

|

|

|

|

|

#72 |

|

Senior Member

Join Date: Jan 2011

Location: sw minnesota

Posts: 4,574

|

well heck no wonder if you dont have chatter rods!, just kidding, i thought they went up to the shoebox. when is the end of the rods? thanks for the education i always get here!!

|

|

|

|

|

|

#73 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

You can cut a flywheel on a lathe...if...there is no hardspots...or...you cut thrue them.

Only time a flywheel meets a lathe here is when they are on a diet...loosing half there weight. |

|

|

|

|

|

#74 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,431

|

A lathe will certainly true them up but a grinder leaves a more conducive friction surface. Sort of like the cross hatch on a cylinder wall makes for better piston ring bedding in.

|

|

|

|

|

|

#75 | |

|

Senior Member

Join Date: May 2013

Location: Pa.

Posts: 2,171

|

The Flywheel grinding machine shown in the video looks a lot like a miniature version of machine I had to learn to run as a Tool and Die Apprentice called a Blanchard Grinder

Quote:

__________________

Nomad |

|

|

|

|

|

|

#76 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,431

|

Blanchard grinders can get a way lot bigger than a flywheel grinder but they both work on a very similar principle.

|

|

|

|

|

|

#77 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

Every new flywheel is just cut...the real reason you grind used flywheels are to deal with the hardspots.

|

|

|

|

|

|

#78 | |

|

Senior Member

Join Date: May 2010

Location: East Shore of LAKE HOUSTON

Posts: 11,113

|

Quote:

http://www.fordbarn.com/forum/showth...=152238&page=2 .......which states: "Pressure plate and clutch were all replaced with new from Fort Wayne Clutch. It, along with the trueness of the crank just put in (it with the flywheel had less than 1/1000th run out whereas the previous crank was 2/1000ths) totally solved my clutch chatter problem I've suffered with for a year and a half. That was sure nice. I sure hope any redoing of the engine doesn't undo that nicety." I'm having a hard time understanding YOUR recollection of the clutch chatter. Back then you said the new clutch "totally solved my clutch chatter problem". Now, you state that this Ft. Wayne Clutch was bad from the start, 38K miles ago. Which is it? DD |

|

|

|

|

|

|

#79 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

Someone here must have a measurement for the depth,from flywheel clutch surface

to the flange surface that the bolts head seat on.That will determine what was removed from previous machine shops. The flywheel resurface was done on a grinder as the pattern is viable and not on a lathe. Run out must be taken to confirm it as square to the mounting surface. R |

|

|

|

|

|

#80 |

|

Senior Member

|

Heres the Borge setting jig it uses a 7mm spacer in three places to simulate the plate/disk, I think you could do the same with a venire on your fly wheel .the first pic is a diaphragm clutch that could be substituted for a ford one ,not sure of the brand .Ted

Last edited by FlatheadTed; 04-05-2017 at 08:52 PM. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 03:02 AM.

Linear Mode

Linear Mode