|

|

#101 |

|

Senior Member

Join Date: May 2010

Location: Homestead, Fl

Posts: 351

|

I second all the above. I get upset when you take TOO long in between posts! With me doing a coupe I get extra pleasure seeing what you are doing.

|

|

|

|

|

|

#102 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

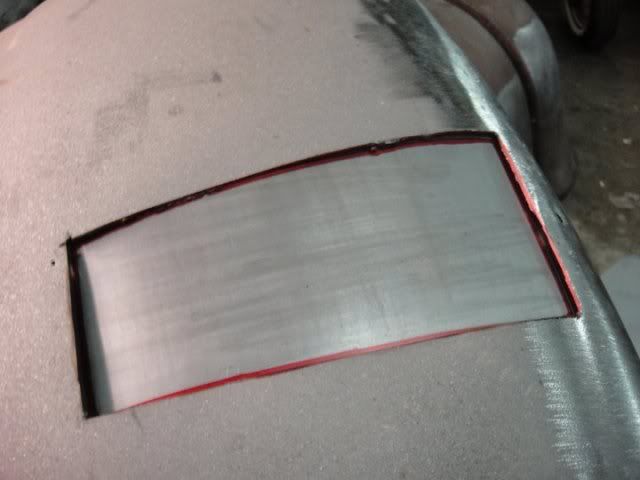

well these are a set of splash aprons that looked decent until i got em back from the blasters.sand blaster always finds all kinds of nice things for me to fix!

this was all lap tacked i guess you could call it.  i ran a grinder down the slit to make it a butt weld

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#103 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

heres a fender i did recently with the hole for the tire.

yeeeeah i dont even know what causes damage like that.        gettin there     rear brace where it meets the running board    new pan had to be put in since the old one has seen better days   45 spot welds later

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 10-01-2011 at 07:32 AM. |

|

|

|

|

|

#104 |

|

Senior Member

Join Date: Jul 2010

Location: Aiken, South Carolina

Posts: 695

|

This is one of the best posts I have seen in a long time. Having done all of this kind of work, I studied each picture carefully. Superb! It is great seeing these repairs done correctly. Tons of work, but it is done right when you are finished-no doubts, no bondo, no cheating. Just solid and beautiful. Well done! Keep showing us more.

|

|

|

|

|

|

#105 |

|

Senior Member

Join Date: May 2010

Location: So Cal

Posts: 8,741

|

How about putting some of this on YouTube so we can see how it's done.

Bob |

|

|

|

|

|

#106 |

|

Senior Member

Join Date: May 2010

Location: Maryland

Posts: 145

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#107 |

|

Senior Member

Join Date: Oct 2010

Posts: 837

|

Jeez my right hand is numb. But certainly worth it!

|

|

|

|

|

|

#108 |

|

Senior Member

Join Date: May 2010

Location: Pitt Meadows BC

Posts: 1,003

|

Flop I have a question. When showing shots of your sheet metal patches, it is evident that you work and finish weld one edge at a time. Subsequent shots show the original tack welds and the patch is finished one side. Can you educate me on this method?, as I have always tacked all around until the joint is complete, (keep the heat down by spacing the welds) then finished the grinding/filing until I am happy.

|

|

|

|

|

|

#109 |

|

Senior Member

Join Date: May 2010

Location: Takoma park md

Posts: 271

|

how do you avoid pin holes and the little weld edges that always seem to need to be filed down?

__________________

Rust and roll will never die |

|

|

|

|

|

#110 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks greg!

Bob that would be an 8 hour long youtube video on this fender! thanks rancho.little too much info Milton hahaha Farrell this method works for me. but if ya think about the jumping around method on a panel that is 4 by 4 inches your are still gonna heat up the whole area anyway. i love working a panel from one side to the other.i can make the finished work keep going.hard to explain but sometimes you get the right amount of crown /warpage from the heat.this just works for me . i never seem to get pin wholes with a tig i get occasional pits though. i do a ton of hammer and dolly work on the weld and on the edge of the weld.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#111 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

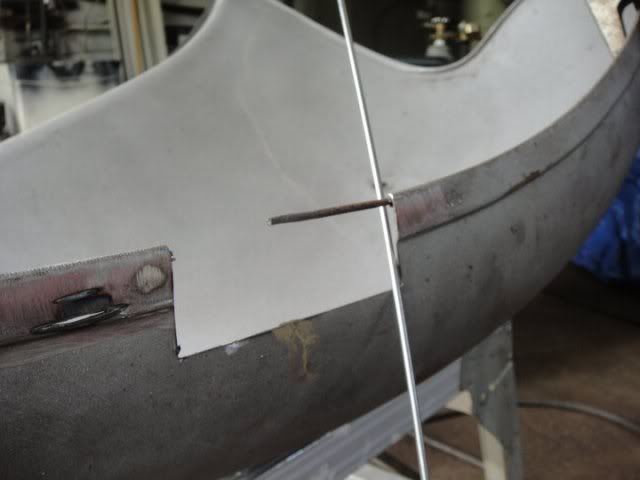

well heres another fender that was in nice shape but a hack job of removing the spash pan that was attatched

getting it together   clamped

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#112 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

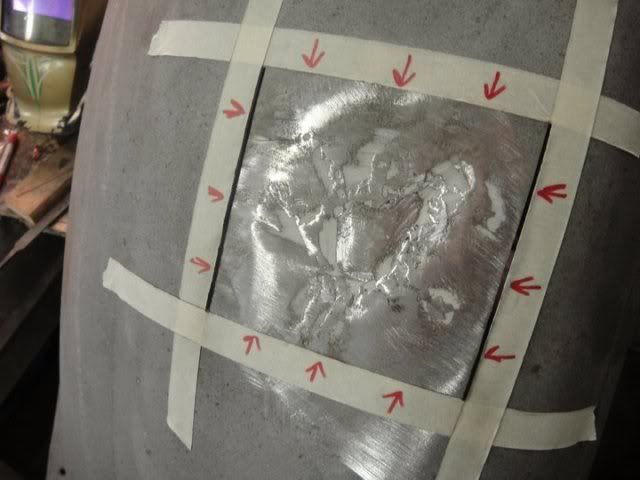

justa little patch i put in in

this fender is a train wreck but he wants it fixed so fixed it will get     ill show the rest when its gets finished up !

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#113 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

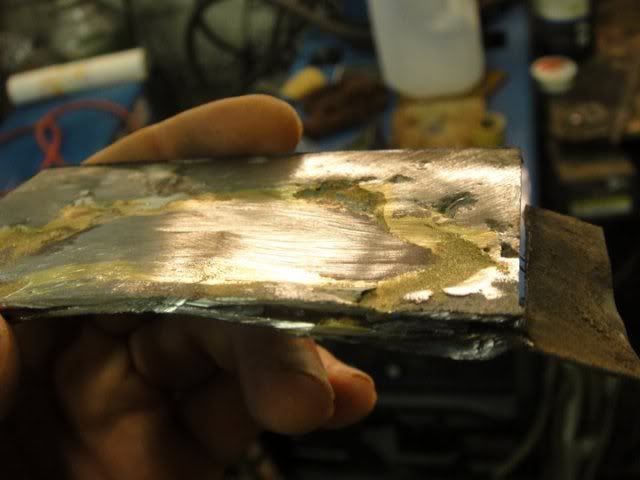

mmmmm brass and double paneled...needless to say that got cut out

new holes getting lined up and welded in.measured from 3 different place on a very nice model a fender so it should be pretty close to the right spot  one high spot i see haha.ill take care of that tomorrow

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#114 |

|

Member

Join Date: Mar 2011

Location: Los Angeles

Posts: 45

|

this is good stuff. Nice work, I am gonna be doing a bunch of patch panels soon and this is really helpful.

|

|

|

|

|

|

#115 |

|

BANNED

Join Date: May 2010

Location: Walla Walla, Washington USA

Posts: 6,066

|

Very professional Flop...Thanks for sharing your wonderful talent with us here on Fordbarn!

Pluck |

|

|

|

|

|

#116 |

|

Senior Member

Join Date: May 2011

Location: Snohomish,Wa.

Posts: 139

|

Hi Flop, just sent you an E-mail to get a price quote for you to work your magic on my 1930 Model A 4dr sedan rear fenders....Your work is ausome.....Dave

|

|

|

|

|

|

#117 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

glad i could help ollin

thanks steve!! appreciate the kind words! hopefully we get to work together soon dave! heres the finishing touches to the fender finished up another fender this morning some more stellar work  patch i made .a little english wheel action on it   last weld on it     badly brazed in  had to put a new pan in it as well. the ends were really bad they had to be cut out of the fender  and thats where my camera died but here it is finished up.the customer said the fender was gonna be junk i said naaaah its fixable now he has a perfectly good usable fender!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#118 |

|

BANNED

Join Date: May 2010

Location: Walla Walla, Washington USA

Posts: 6,066

|

FLOP...Awsome man!

That is a lost art that many of us do not know what to do! Simply Awsome! To bad you are on the East Coast! Pluck |

|

|

|

|

|

#119 | |

|

Senior Member

Join Date: Aug 2010

Location: Winchester VA

Posts: 154

|

Quote:

There's a line forming...  I just drove from Winchester VA to Pittsburgh yesterday to drop off my '29 rears to have Flop save them for me. After the all the paint and filler was taken out when blasted it became even more evident that it was not something I could handle. Maybe I'll see his progress on them here!!

__________________

No time to play my Gibson RB-250 anymore.. Maybe.. One day... |

|

|

|

|

|

|

#120 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks again steve

yours are next miles! his fender is another fine specimen of fantastic work   mmm brass and screws!    the bead rod was broke as well   used my bead roller to make the step    next fix the mess and get the pan to fit  just used the break to make the bend and a little shrinker stretcher action to get the curve.  i have to use a paper template to make this i can never get it in one piece ...     only 4 more feet of welding to go haha

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 04:22 AM.

Linear Mode

Linear Mode