|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#41 | |

|

Senior Member

Join Date: May 2010

Location: Cen~Col - Central Highlands

Posts: 2,757

|

Quote:

Look at top to left and slightly above the blue spot on the picture ... right side of the part that goes to drive shaft ... Vertical part is shiny and horizontal part shows signs of rubbing too. Click picture to enlarge Cannot be seen when viewing small picture Last edited by Benson; 06-03-2012 at 07:22 PM. |

|

|

|

|

|

|

#42 |

|

Senior Member

Join Date: May 2010

Location: Cen~Col - Central Highlands

Posts: 2,757

|

As before ... enlarge picture to see it.

Maybe I am just seeing things ... After 50 years of troubleshooting problems and looking for trouble. Last edited by Benson; 06-03-2012 at 09:30 PM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 |

|

Senior Member

Join Date: May 2010

Posts: 4,179

|

Kevin,

With only great respect for your valuable time, , I'll try to explain this re-occurring Model A mechanical concern with a simple parable. It is really as simple as this: 1. You are in a hotel corridor with closed, locked doors on both sides of you. 2. You hear a "knocking" noise which resonates throughout the corridor. 3. You make a video of the hotel corridor with the closed, locked doors, accompanied with the sound of the "knocking" noise; & you ask "what" is making this "knocking" noise; and "where" is the noise coming from. 4. Confusing answers begin to come in: "Try Hotel Room 103; try Hotel Room 106; it's a hotel maid locked in Room 105; its an open widow in Room 107 with a set of blinds banging in the breeze." 5. Good intentions from kind, experienced individuals; but nothing is resolved because being miles away, one cannot see the Hotel Room doors vibrating, one cannot experience the "actual" sound, & the worst part is, none have Room keys to investigate inside the Rooms. 6. So far you have done an outstanding job. What you are doing is not easy for any of us. You already opened the "Engine Starter Room 103 door", & no knocking there; you removed the flywheel cover to peek in Room 108; however, the main source of the kocking has not been found yet. 7. As we all do, just continue looking; but, as suggested, isolate components by taking one Hotel Room at a time, such as "Engine Room No. 101, by itself", suggested by Tom, & even open the door & look around inside if need be; also the "Clutch Pilot Bearing Room 109" suggested by James. 8. Even though today it appears confusing, highly technical, & complicated, when you find the cause of the knocking it will "always" be something simple -- like maybe some drunk sitting in the Hotel Room humming Dixie, & keeping time to his humming by tapping his empty wine bottle on TV screen. 9. Many of us get stressed concentrating on the unknown; then we laugh & open a beer when the problem is resolved. 10. You have the Room Keys -- wishing opening time will be soon & relaxing for everyone. Last edited by H. L. Chauvin; 06-04-2012 at 11:42 AM. Reason: typo |

|

|

|

|

|

#44 |

|

Senior Member

Join Date: Nov 2011

Location: B.C. Canada

Posts: 1,746

|

Have you pulled the drain plug on the rear end to see if any pieces come out?Some times rear ends can be quiet at low speeds but will be noisy in high gear.I never unhook the exhaust when pulling the R-E.I use axle stands made from 42-48 axle hsgs with a piece of 3" channel welded on top.I place them under the frame just ahead of the rear running board braces& it just clears the exhaust & front of radius rod.

|

|

|

|

|

|

#45 |

|

Senior Member

Join Date: May 2010

Location: Auburn, MA

Posts: 2,106

|

If Benson is right it may be due to the inherent characteristics of the transmission where the direct drive on third gear is pusing the u joint back just far enough to rub. That is a wild stab but the only idea I can come up with.

__________________

“The technique of infamy is to start two lies at once and get people arguing heatedly over which is true.” ~ Ezra Pound |

|

|

|

|

|

#46 |

|

Senior Member

Join Date: May 2010

Location: Santee, California

Posts: 3,505

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#47 | |

|

Senior Member

Join Date: May 2010

Location: Cen~Col - Central Highlands

Posts: 2,757

|

Quote:

Wasn't there a problem a few years ago with the reproduction transmission cases? Something about the rear main bearing retainer being the wrong size or bearing machined area was the wrong depth? I wonder if both of these transmission cases (the first one and the replacement) are Ford originals or Repros? |

|

|

|

|

|

|

#48 |

|

Senior Member

Join Date: Jun 2011

Location: Oakton, VA

Posts: 438

|

The experience, knowledge, analysis, kindness, willingness to help and encouragement on this thread, is so impressive-it makes me feel I'm in a neighbor's garage watching a couple of dozen friends helping another friend in need.

|

|

|

|

|

|

#49 |

|

Senior Member

Join Date: May 2010

Location: Cen~Col - Central Highlands

Posts: 2,757

|

Kevin,

Fortyfive years ago I fought a similar noise problem on the Coupe. Noise was very intermittent and VERY loud. Happened at 40 -50 on the highway. Noise was so loud that I ALWAYS stopped the car right away. It sounded like the car was going come apart! Sometimes the noise started up again after 2-3 minutes stopped on side of road. But mostly it did not occur again for a day of two. Disconnected fan belt. Used stethoscopes etc and etc. 10 or 12 experts were consulted. Several even heard the noise. Everyone agreed it was in the transmission or rear end. I was using the car as my only transportation to work and school so every Monday morning it had to be running again I would put it back together and use it for the week and each time the damned problem came back no matter what we did. I removed the transmission and/or rear end a total of 3 times each, loaded them into Dad's microbus on Saturday and took them to Golden Restoration for the experts to go over and find the problem. Nothing was ever found to be wrong. Bearings and gears and etc were replaced. This went on for 6 weeks of R&R parts on weekends. Finally I got so mad that when the noise started the next time I sped up to about 50 instead of stopping and let the damned thing just howl! After 30 seconds or so I heard different noise from the area of the speedometer and looked down to see the speedometer bouncing up above 75 and back down over and over. The whole problem was that the bushing in the speedometer was dry and making all that noise all along. A few drops of oil and it never did it again. So Don't give up!!! Last edited by Benson; 06-04-2012 at 06:43 AM. |

|

|

|

|

|

#50 |

|

Senior Member

Join Date: May 2010

Posts: 4,179

|

Kevin,

Many older generation members in Clubs today can now laugh at all of yesterday's concerns & problems when Model A parts were not readily available. My first $25.00 Model A Coupe came with (11) "may-pop" spare tires with (11) heavily patched Pre-WWII red rubber inner tubes, all mounted on (11) wheels. Six (6) of the (11) spare tires had "boots", i.e., thick rubber tire patch inserts to patch blown-out ruptured holes in tires. This car was also adorned with two (2) "operable", opaque RC Cola Drink, commercial metal signs for door glass, on both the driver's & passenger's side. It had a rear end that sounded like a corn grinder connected to an amplifier -- never needed a horn -- rural pedestrians, bicycle riders, cattle & dogs could always hear me coming. A month or so later, the former Model A owner gave me an original 7" wide x 7" high x 18 inch or so long 6 volt 1930's AM radio that he had since the 1930's. Got it all hooked up, & it sounded fine while parked -- then I took off, shifted in gear, then the corn grinder rear end totally drowned out the music. We learned a lot about Model A mechanical & electrical things through self-education while struggling to make pure junk work; & we were always happy with almost nothing. While almost broke, being towed home was out of the question -- if something mechanical or an electrical item failed along the highway, we did something many youngsters today never were taught -- "think"! You may not realize it yet Kevin, but you are already one of us! Last edited by H. L. Chauvin; 06-03-2012 at 11:17 PM. Reason: typo |

|

|

|

|

|

#51 | |

|

Senior Member

Join Date: May 2010

Location: Lindenhurst, IL

Posts: 793

|

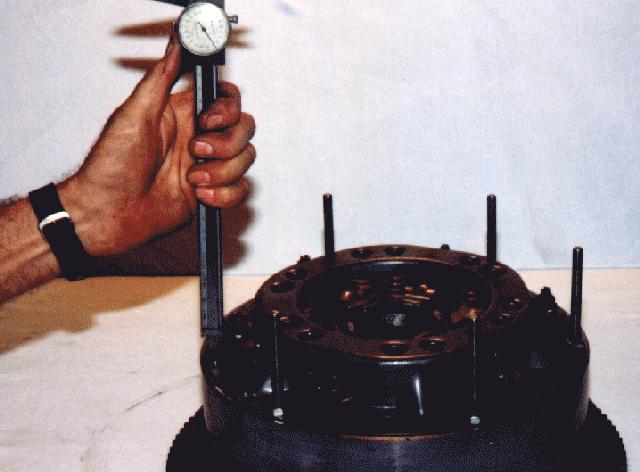

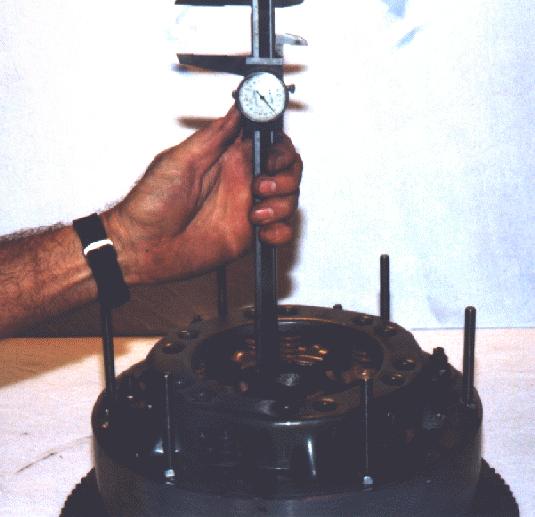

Quote:

Per the following the measurement is done on the pressure plate; 12) With your piece of 5/16" i.d. tube slid over one of the adjuster bolts, and the screwdriver in the slot, adjust the nut until you get a distance of 11/16", measured from the top face of the rear of the lever, down onto the cover.  13) The lever should now be just above the horizontal plane in relation to the flywheel face, so now take a measurement from the throwout contact point of the lever down onto the clutch plate, and set the rest of the levers to this same height.  Just more info, GW |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 04:42 PM.

Linear Mode

Linear Mode